Adding a new dimension to traditional channel letters with 3D printing

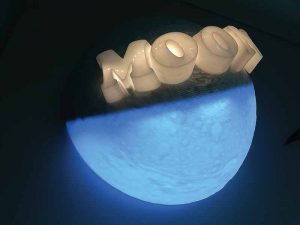

By creating a design file in 3D from the start, all aspects of the letters can be included in the design process. This means the creative possibilities are endless. Brands can incorporate unusual shapes, curves, different angles, and side textures and need not produce one letter at a time or letters at all for that matter. The flexibility and freedom of this printing process enables users to produce cursive words, a logo, or graphic elements of a logo, such as a teddy bear, globe, or coffee cup. Products and mascots can be printed as separate, eye-catching signs or incorporated within the letters. Additional eye-catching features, such as light-emitting diode (LED) lighting or video mapping, can easily be added to 3D printed channel letters for enhanced visual impact. One starts to see the tangible benefits 3D printing delivers to companies when evaluating the challenges signmakers using aluminum endure while creating letters (like ‘O’) with an empty cavity.

Reduced production errors

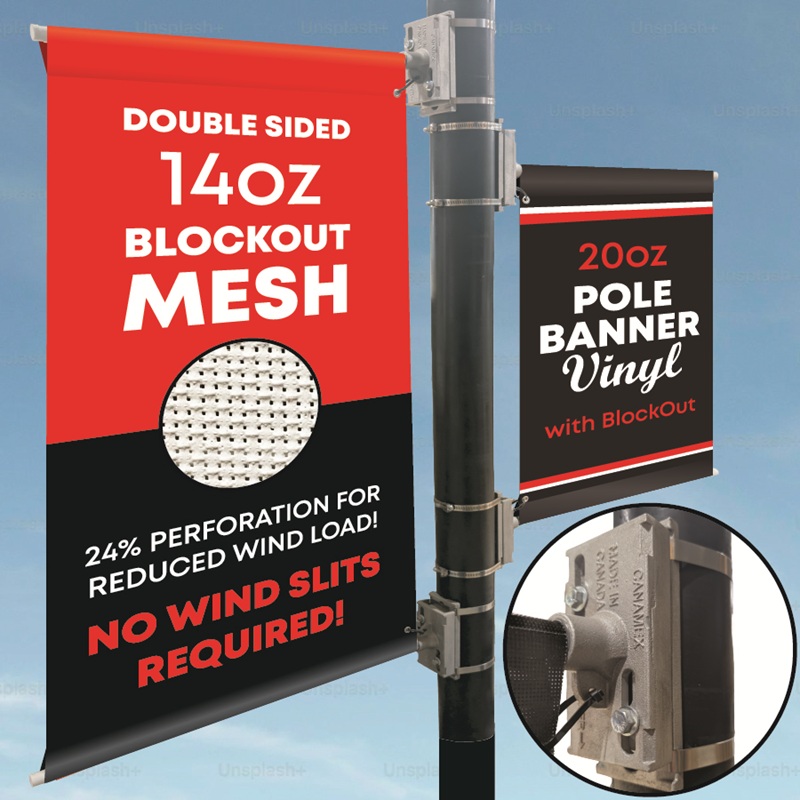

Using 3D printing technology, complex, creative signs can be created at a significantly higher speed than traditional methods. Other than reduced time and manual intervention, a 3D printing solution designed to produce large-format visual applications can also create attention-grabbing retail signage, high-impact vehicle wraps, and crowd-stopping event and exhibition displays. Those 3D printing solutions that offer dual printheads can also print two models simultaneously, making production even more cost-effective and also lowering the cost for the end customer.

Reducing the manual elements of the production process also diminishes production errors. For example, by amending the design on screen, such as adjusting the curve of a letter before sending it to the 3D printer, the user can eliminate any errors and avoid costly iterations altogether.