UV printing, unbound

How UV drives MacLaser Printing forward

Sometimes in life, one good thing leads to another. Take, for instance, MacLaser Printing Company co-founder Sal Indovina, who, together with his brother Joe, was part of a group of neighbourhood kids racing go-karts in the ‘80s. They wanted to move up to open-wheel race cars. To finance their hobby, Sal got a student loan in 1985 and used it to buy a laser printer. He then applied his computer programmer analyst training from Seneca College to the newly introduced Macintosh computer, using the laser printer to output his designs.

Sal and his brother began printing resumes and flyers on the side, officially launching MacLaser Printing in 1989. Since then, Sal has grown the business to include commercial printing, wide-format printing, custom labels, engraving, embroidery, and apparel customization. Most recently, MacLaser acquired ultraviolet (UV) flatbed printing capability to print directly on sports gear, coroplast, and other products and memorabilia. “We’ve found that having in-house UV printing capability allows us to provide the quality we are seeking for our clients,” says Sal.

We talked with Sal about how he built MacLaser Printing, how they have evolved their product mix over time, and how their production environment today reflects the changing marketplace.

Ginny Mumm (GM): What steps did you take in building MacLaser Printing?

Sal Indovino (SI): We’ve grown steadily since we were founded and added products over time to meet the market’s needs. We started our printing business at home, but eventually my mom kicked us out because she was tired of people coming over.

We found a 148.6 m2 (1,600-sf) industrial unit and put an office in the front, with our race shop in the back. We bought a photocopier and later added a printing press. Over the next few years, we bought the supporting equipment needed for commercial printing, including a cutter and a Cerlox binder.

When we got more business, we bought the industrial unit next to us. Then we added spiral binding and die-cutting capability. Eventually, the two industrial units put together just weren’t offering us a great flow for production, so we looked for another, larger space.

GM: Where are you located now, and how is your facility arranged?

SI: We bought a 464-m2 (5,000-sf) building in Mississauga, Ont., which is where we are today. It’s in a more upscale industrial area called the Airport Corporate Centre. There’s not much foot traffic, which is fine because our business comes to us through referrals. We have a 185-m2 (2,000-sf) office and production area, plus an additional 278 m2 (3,000 sf) of dust- and climate-controlled production and finishing space.

Over the years, we’ve brought in a four-colour press, heat press, embroidery machine, digital printing equipment, a direct-to-film (DTF) printer, and larger binding and contour-cutting equipment. Our latest addition is the Roland DG VersaOBJECT CO-300-F200 30-inch UV flatbed printer. We work with high-end clients, and we like to control as many aspects of our production as possible.

We currently have three full-time employees and four part-time employees. We don’t have any salespeople. I work in production and am training another employee to help with production. My wife runs the office, and my daughter handles embroidery.

GM: Where are most of your clients located, and what industries do you serve?

SI: We have clients located everywhere from Spokane, Wash., to Montreal, Que. Our customers include a couple of National Hockey League (NHL) teams, several Ontario Hockey League (OHL) teams, and one Western Hockey League team. We also serve companies in the automotive, medical, retail, and business sectors, as well as providing products for the Golf Canada Foundation.

GM: At what point did you decide to begin offering UV printing?

SI: We decided to add UV printing capability because we’re a small shop that likes to do things in-house, and making name plates for players on the hockey teams we serve had been a huge manual task. We’d have to print each name plate on vinyl, then apply it to styrene and laminate it, then hand-cut the styrene. We typically produce 200-300 name plates per season, and we’d often get a call at 11 p.m. to make a new player’s name plate—and it needed to be ready to go by 6:30 a.m. the next day.

Adding the UV flatbed printer saved me from hiring additional employees to do this job. In recent years, we’ve seen a reduction in printing mailers, so we sold our commercial printing press and used the money to buy our UV flatbed. Now we can print names directly on the styrene, saving many hours of labour each season.

The printer has given us the ability to do other things that we couldn’t do before, and it’s made my life easier. Now we can print directly on hockey sticks and pucks, and we even produce UV-DTF transfers (printed layers of ink that can be applied to hard-to-print-on surfaces) to brand one team’s coffee pots.

GM: How did you decide which UV printing equipment to purchase?

SI: We were looking for a printer that offered good height clearance. Initially, we looked at GCC’s offering—we have their 100-watt laser—because their UV printer can print on a suitcase, but they wouldn’t bring it to North America unless we ordered 10 of them. We had heard about Roland DG’s UV printer and liked that it offered a 203.2 mm (8-in.) height allowance. The print quality is also excellent.

In addition to printing on thicker objects, we’ve enjoyed using the white and gloss ink to incorporate texture. For one of our clients, we produce a board that holds the pucks from every game they win each season. We added texture to it, and that feature alone helps our printing stand out from the competition. People ask the staff, “Where did you get that done?” Each team is always trying to outdo the other on and off the ice, and anything we can offer that helps to set them apart is a benefit for our business.

GM: What do you see ahead for your UV-printed production?

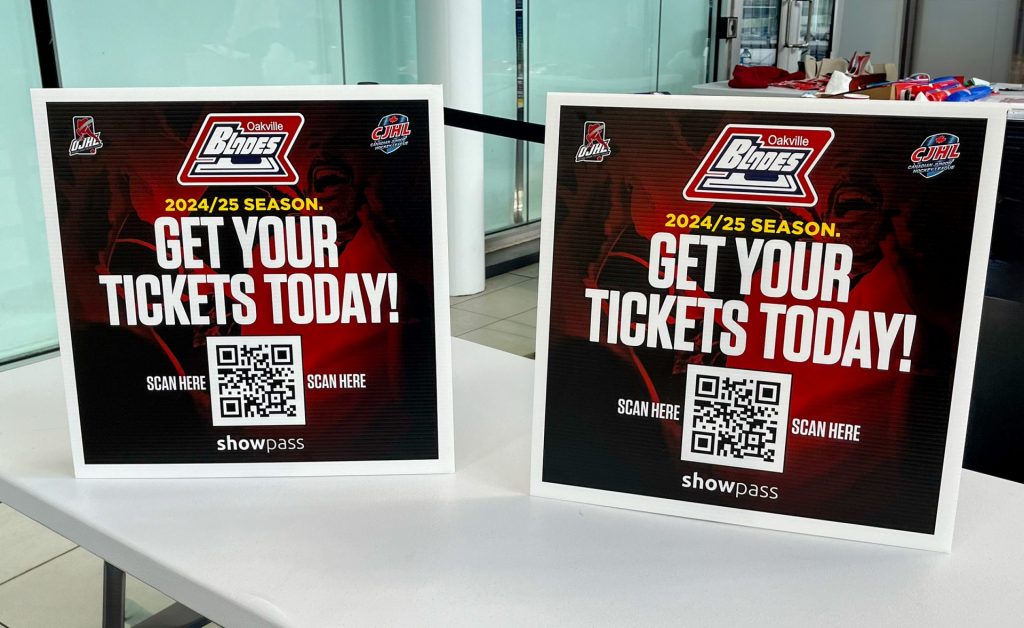

SI: We’ve been discovering other ways to use our UV printer. For example, we can print directly to Coroplast, which has allowed us to bring that production in-house for one of our clients.

Next, we are going to try printing on a football for a customer who gives away footballs every time the team reaches milestones.

GM: Why do you think your customers choose to do business with MacLaser Printing? What sets your shop apart from the competition?

SI: I think our customers appreciate that we can offer them so many different types of products. They can come here and get custom-printed t-shirts, embroidery, flyers, booklets, memorabilia, promotional products, and Coroplast signs. We have the state-of-the-art equipment and experience to deliver a wide range of high-quality products.

We’ve never advertised and rely exclusively on referrals. In addition to having a good reputation, clients seem to appreciate that we’ve been here for 30 years. In fact, we still have some of the same customers we started with.

Ginny Mumm is a freelance consultant for digital inkjet printer/cutter provider Roland DGA. For more information, visit www.rolanddga.com.