Sunshine Graphics: Rising from the ashes

After many years running the shop, Landen Ehnes was proud to succeed his father as the owner of Sunshine Graphics in Vernon, B.C. But last September, during Landen’s first year as owner, a fire burned the shop to the ground.

Landen talks about why he wanted to follow in his father’s footsteps, how the fire has impacted his business, and what he’s doing to ensure Sunshine Graphics returns stronger than ever.

Ginny Mumm (GM): Tell us how your interest in signs and graphics grew.

Landen Ehnes (LE): I started working at Sunshine Graphics when I was nine. My dad had been a photocopy salesman who absolutely hated the job. His friend at the time knew of a solid business in town that was up for sale. My dad, knowing absolutely nothing about the signage industry, decided to buy into Sunshine Graphics with a business partner.

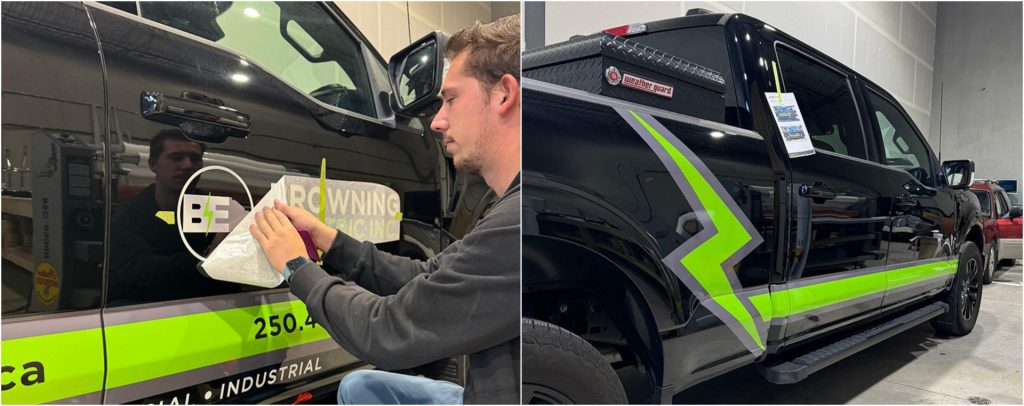

When I first started here, all I was doing was emptying garbage cans, sweeping the floors, and picking up decal scraps stuck to the floor. I made Cdn$5 per hour and could only work during the summers, but it was something to do. When I was 17, I was trained for the first time on paint protection and vehicle wraps. That led me down the path of learning about signs and graphics until I knew this business inside and out—from graphic design to production, installation, and finally to completed projects.

GM: How long have you owned and operated Sunshine Graphics?

LE: This is my second year of officially owning the business, but essentially, I’ve been running it for the last five years.

GM: Please tell us about the fire.

LE: The fire broke out on September 4, 2024. As a new owner, it put my skills to the test. There is absolutely nothing you can do to prepare yourself for something like that.

Luckily, no one was hurt, but everything in the building was a complete write-off—computers, plotters, printers, films, tables, work orders, tools—all burnt to a crisp or completely melted. We had a client’s brand-new GMC 3500 in the shop, fully wrapped and ready to present the following morning; it burned, too.

To be an entrepreneur, you need to be good at roadblock management and quick on your feet to get past all the pitfalls. I believe this to be true in any business—to survive, you need that critical skillset.

GM: Where is your shop now?

LE: We had a long-time client who owned a brand-new multi-use commercial building with one spot that was not leased and which he was saving for himself. Out of the kindness of his heart, he let us rent that space. It’s smaller than we’re used to, but it allowed us to get up and running fast.

In two weeks, we were operating at about 85 per cent. I was beyond stressed as our largest client placed their biggest order ever, just four days after the fire. I was doing everything in my power not to lose that account. You know how sometimes your neck hurts when you sleep wrong? Mine hurt because I was on the phone 24/7, lining up supplies and equipment.

GM: Tell us about your rebuilding efforts. What will the new shop look like?

LE: We are rebuilding at our old shop’s location. It’s centrally located in town, with dealerships close by. We have almost too many walk-ins, along with many clients who schedule time for consultations for graphics and/or paint protection film or tint.

The new shop is going to be game-changing. In our old shop, we had just under 279 m2 (3,000 sf), which we were quickly outgrowing. Our new facility will be 743.2 m2 (8,000 sf) in a two-storey arrangement. Downstairs will be completely dedicated to reception and installations. Upstairs, we will have our production area with all our printers, tables, and laminators. The space should be more than adequate and leave us room for growth.

GM: How many employees do you currently have?

LE: I have two graphic designers, who also assist with answering the phones, three main installers, who handle the tinting, paint protection, and vehicle wraps, and two part-time employees I can call on for outside installs. I essentially float to assist with any given task. These days, I’m spending a lot of time on production as we haven’t yet found someone who can keep up with the demand.

GM: Which printers are you using?

LE: Ever since my dad bought the business, we have been a Roland DG shop all the way. I don’t remember the model of our first Roland DG printer, but it was a tank and an absolute workhorse.

Roland DG printers have been tried and true for many years. When I look at my business and how it operates, I see that our success is in our consistency. We have minimal downtime and maintenance, our colours are the same every time—it doesn’t matter if there’s a temperature change—and our efficiency is improving. Honestly, I have explored other printing equipment options and spoken to fellow industry owners with different setups, and I circle back to Roland DG every time.

We currently have a 54-in. Roland DG TrueVIS VG3- 540 large-format eco-solvent printer/cutter, and we just acquired the new 64-in. TrueVIS XP-640 high-speed printer. My designers were fighting over the VG3, and when I saw how productive and efficient the XP-640 is, I knew it would be a great addition for our shop. It absolutely flies through vehicle wraps. It has cut our print time three-fold. In our world, efficiency is make or break.

The XP’s colour palette offers us the best range of colours we’ve ever had, and the way it can power through big, long, heavy ink prints is unbelievable. We use cyan, magenta, yellow, key (CMYK) ink, and orange, green, and red inks. We have the option to double up the CMYK and print even faster, but this machine is already way faster than our VG3.

GM: How is your output divided between signs and graphics, as well as vehicle graphics and wraps?

LE: Our business is about 50 per cent graphics and signage, and 50 per cent vehicle graphics/wraps. The other side of our business is in vehicle protection, including ceramic coating, window tinting for residential and automotive, and our bread-and-butter—paint protection film.

After the fire, it was like our business was on steroids. Everything was amping up big time. The publicity and public support we received boosted demand for our services.

GM: Does your shop offer print and ship services?

LE: Currently, we don’t offer print-and-ship services, but we’ve been looking into it more. It’s hard to compete with the Amazons of the world, but there are some lucrative avenues we’re actively exploring.

GM: As far as vehicle graphics go, what’s most popular in your shop these days?

LE: Clients are starting to realize how effective vehicle advertising is, and most can see the value in full wraps. Others choose partial wraps or lettering, which can also be effective for promotional purposes. It’s a broad range, and we don’t try to steer customers in any particular direction, as they know their business best.

As far as fleet graphics go, we have one plumbing and heating company that has done 55+ vans with us in five years. We see them everywhere we go. Many of our other clients have anywhere from five to 10 vehicles in their fleets that they need wrapped, ranging from service trucks to trailers and transit vans.

GM: Who are your clients in terms of size and the industries they represent?

LE: We work for a lot of small to medium-sized companies. Construction trade shops are a big source of business in this area of the Okanagan, B.C.

We provide service primarily to clients located in or near Vernon, B.C., since travel is quite expensive, and honestly, there are a lot of amazing shops in this world. If a prospect is from another town, I usually send them to a shop that’s local to them.

GM: How do your clients find you?

LE: Vernon is a big word-of-mouth town. I do some YouTube advertising. I have had people stop me at the grocery store and say things like, “Hey, you’re the guy from the commercial!” So, our ads seem to be working.

GM: It’s a crowded field, so why do your clients choose Sunshine Graphics?

LE: They choose us because we are real; we don’t pretend to be perfect. We are humans putting very large custom-printed panels on vehicles. When there are mistakes and errors, I first call my clients to explain what happened, and more importantly, my plan to correct things. The more you try to fool your clients, the less credible you are. Wear your mistakes like a pair of shoes, check your ego, and get any problems fixed in a timely manner.

I often tell my staff not to be afraid to make mistakes, it’s all part of the journey. No one is perfect, and no install is absolutely flawless, but you can get really close. I believe our clients see that we do everything possible to deliver high-quality work and genuinely care. In an often-phony world, it’s rewarding to be authentic, and that’s what people truly want.

GM: What lies ahead for Sunshine Graphics?

LE: There are so many opportunities out there; you just need to know where to find them. That’s truly my job, to go out and blaze the trail. I don’t like to have the business running me; I run the business. I also believe the emergence of AI will move the needle in our industry in a positive way.

We are fortunate to have the equipment and staff we need to rebuild our business and make it better than ever. Like the proverbial phoenix rising from the ashes, the fire temporarily set us back but allowed me to see the infinite potential. This is just the beginning.

Ginny Mumm is a freelance consultant for digital inkjet printer/cutter provider Roland DGA. For more information, visit www.rolanddga.com.