LEDs: The challenges of illuminating channel letters

Return depth

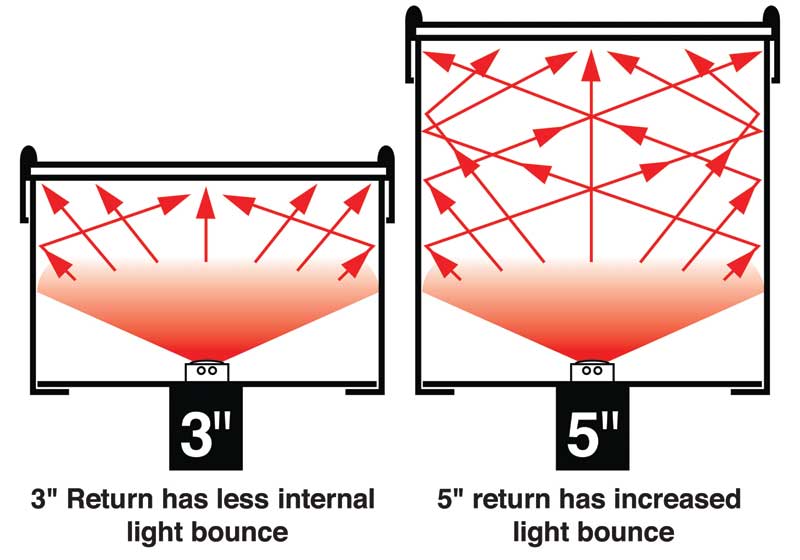

Another factor affecting illumination performance for front-lit LED channel letters is the return depth. (The return is the side of a channel letter, i.e. the actual sign can.)

The current standard return depth for front-lit channel letters is 127 mm (5 in.), which will generally provide an excellent performance for letters that are populated

with the appropriate number of LED modules. That said, a 76-mm (3-in.) return depth is also becoming increasingly common today.

The latter configuration offers a few potential advantages in terms of illumination. First, the shorter distance the light must travel from the LED to the face material leads to an overall brighter appearance. Secondly, the shorter return depth reduces ‘ricochet lighting,’ i.e. illumination that bounces off the sides of the letter before reaching the acrylic face (see Figure 1).

So, while a standard return depth can provide perfectly acceptable performance, the shorter return may result in better LED-based illumination for front-lit channel letters.

Stroke width

The stroke width of channel letters is another factor that will affect the performance of LED illumination. (In this context, ‘stroke’ refers to single line or component of the letter, such as the vertical segment of a capital letter ‘T.’)

Periodically, a sign shop’s clients will submit designs for their channel letters with a stroke width of less than 38 mm (1.5 in.). This can cause issues and reduce the performance of LED-based illumination, as a stroke that small does not allow for the correct placement of the modules.

Hence, a good rule of thumb is for all letter strokes to be at least 38 mm wide. And if the customer’s design has specified a smaller stroke, the signmaker should ask if that specification can be altered accordingly, prior to production.

Number of strands

Another important variable in achieving optimal illumination is the number or concentration of LED strands mounted inside the channel letter. If an insufficient number is used, it can result in a poor appearance.

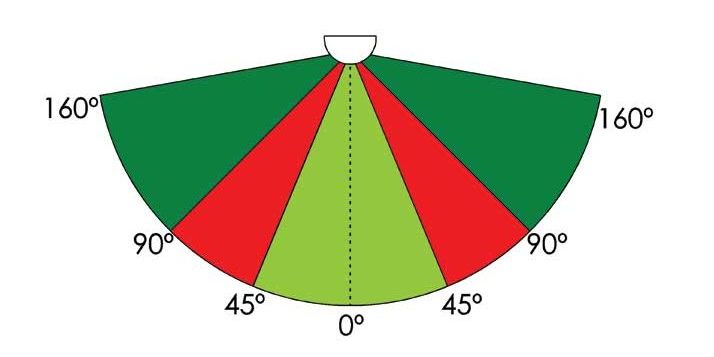

One factor in determining the necessary number of strands is the viewing angle range for each LED module. This range is defined as the area covered by the module’s cone of light before losing 50 per cent of its brightness (see Figure 2).

Such ranges vary between different brands of LEDs, but typically, each interior span of 127 mm (5 in.) requires its own LED module strand. The precise implementation of this common practice will depend on the specific module’s viewing angles.

Return interior paint

Another factor that assists in achieving optimum LED illumination performance is the channel letter’s interior paint or coating.

Highly reflective paint will both enhance the brightness of the illumination and reduce the probability of ‘hot spots,’ i.e. where certain sections of a front-lit letter’s face appear brighter than others.

In comparison, letters where the return’s interior is unfinished will exhibit reduced illumination performance. This guideline applies both front- and reverse-lit channel letters.