How to crack the substrate code

Signmaking with the right materials

When you think of interior signage, there is no one-size-fits-all solution. As a signmaker, your goal is to ensure the signage you produce is as unique to your client’s brand as their business is to the market. It is also essential to recognize that signage is a significant investment for any business, and interior signage can play a crucial role in creating a branded environment that effectively communicates a client’s unique message and enhances customer experience. This often serves as the first introduction to the company.

When thoughtfully designed, it can act as a conversation starter, amplifying the brand and providing clients’ customers with a warm welcome. But where do you start? How do you help clients select the correct substrate when the potential list is endless? How do you stay within their brand’s guidelines?

How can you use signage to help create the atmosphere their business is known for and that their customers have come to expect? And, perhaps most importantly, how can you help their signage stand out?

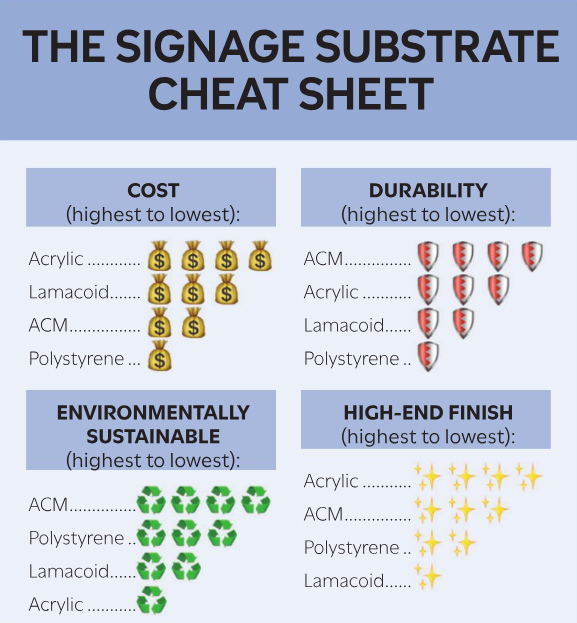

Your first step is to select the substrate. When it comes to substrates, the possibilities can seem endless and overwhelming. When advising your clients, you must consider what material best suits their needs, depending on signage location, cost, environmental standards, branding, durability, and, of course, the final look. This article will focus on four signage substrates and how they can be customized to elevate your client’s final piece.

Acrylic: Premium sophistication

Acrylic signs are made from a clear, durable plastic called polymethyl methacrylate (PMMA). You may have also heard it referred to as acrylic glass or plexiglass. If your client is looking for a high-end, professional sign that screams sophistication, acrylic is the substrate for them. Not only does it provide a sleek and polished look, but it comes in many different thicknesses, allowing you to create three-dimensional letters/pieces that will increase sign visibility.

Acrylic signs boast durability, longevity, and versatility. Acrylic is a shatter-resistant, relatively low-maintenance substrate. It is prone to fingerprinting but can be cleaned easily with mild soap and water. If you choose to print directly onto the substrate versus adhering printed vinyl to the acrylic, signage maintenance will be much easier. Direct printing will result in a longer-lasting, high-quality look, so if you can swing it, always direct-print. Although shatter-resistant, it can be extremely sharp if an acrylic sign is damaged. So, periodic inspections are recommended. Acrylic is also the most expensive substrate option on this list. However, it is more cost-effective than other materials such as wood, metal, and aluminum. The bottom line is, if your client is looking for an elegant, premium-looking sign, you cannot go wrong with acrylic.

Lamacoid: Customizable, yet basic

On the other end of the spectrum, we have lamacoid. Lamacoid is made from multi-ply, multi-colour plastic sheets. Essentially, there are two different coloured plastic sheets—an outer colour and a coloured core—that are adhered to each other. By engraving your design into the top layer, you reveal the coloured core beneath, adding depth by removing material. At Burke Group, we use a laser engraver to produce a crisp and clean final look. Lamacoid is most commonly used for name tags, room identifiers, and industrial labels. Lamacoid is customizable yet basic. Although more than 100 colour combinations are available, they are generally not directly printed onto and cannot be used to produce complex designs. However, it is made of a phenolic resin material, which is nonconductive. This makes it a safe material and is often used in businesses where electrical safety is a concern. Lamacoid is resistant to moisture and harsh conditions, making it an ideal choice for industrial applications.

Polystyrene: Flexible and lightweight

Polystyrene is a lightweight, flexible plastic material derived from petroleum. It can be used for various applications such as indoor or outdoor displays, frame inserts, hang tags, safety signage, and more. Polystyrene can be rolled, flexed, and permanently heat-bent. It comes in a bright white finish, so when colours are directly printed onto polystyrene, the sign pops and creates an eye-catching final look. Polystyrene is a highly economical and customizable material, balancing cost and versatility. However, its thin structure may not make a striking visual impact. If protecting the environment is essential to you and your clients, then you can feel good about purchasing polystyrene, as it is a recyclable material. As a bonus, thanks to polystyrene’s lightweight nature, you will save on shipping costs, and installation is relatively simple compared to other, more heavy-duty substrates.

ACM: Cost-effective and durable

Aluminum composite material (ACM) comprises an aluminum composite exterior with a polyethylene interior. This substrate consists of two metal faces with a plastic core. This means your client gets the high-quality look of aluminum without the price tag. ACM also aligns with sustainable business practices thanks to its energy-efficient production process and recyclable components. ACM is incredibly versatile; it is both lightweight and easy to handle while offering durability and a rugged aesthetic finish you can only capture with aluminum, at a fraction of the cost. ACM is a low-maintenance, visually appealing solution for your client’s signage needs. It also comes in many unique finishes, such as brushed gold, mirror, and standard aluminum. ACM is renowned for its ability to endure harsh conditions and even bend to shape without breaking due to its high ductility. ACM is a cost-effective and environmentally friendly substrate.

Customizations

Choosing the perfect substrate to meet your client’s needs is essential, and ensuring it suits their brand is equally important. Their business is unique, and their signage should be, too. Here are some compelling examples of customizations and the optimal substrates needed to enhance their effectiveness:

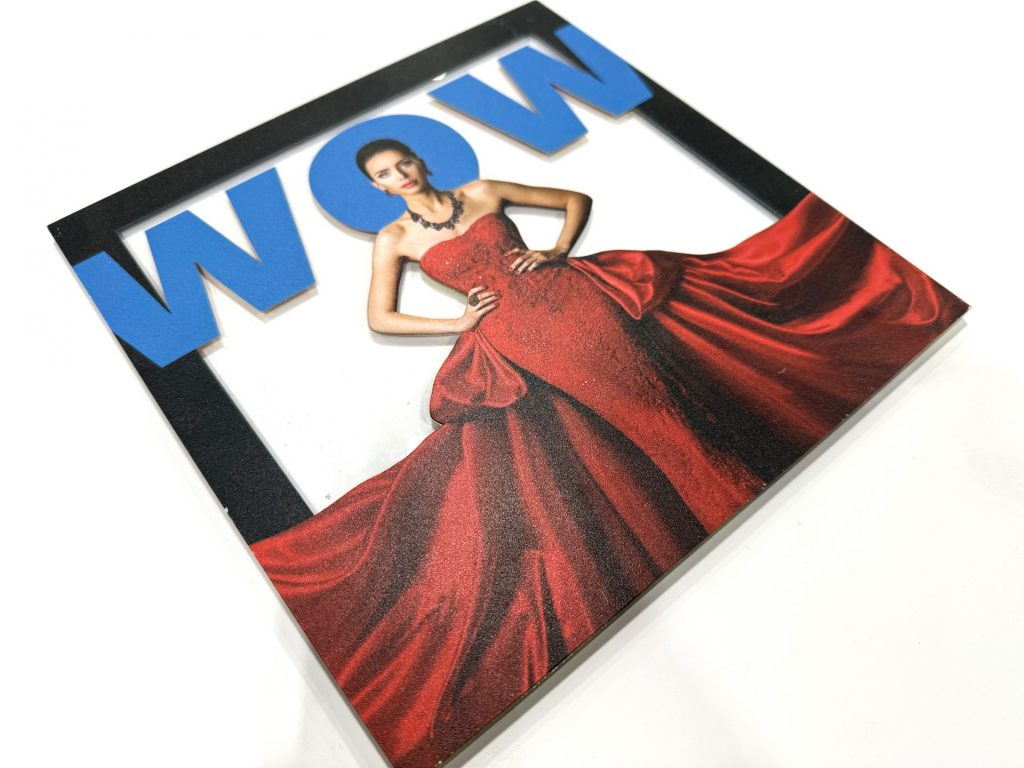

3D textured printing

Adding 3D textured ink to your client’s sign will create a significant impact. Burke Group uses a SwissQ Impala 4 Flatbed printer to create true 3D textured prints. By utilizing layered ink applications and ultraviolet (UV) curing lamps, one can create raised images, textures such as wood grain, enhanced raised design styles, and even braille. Precise registration ensures each layer aligns perfectly, ensuring the sign’s details are perfect every time. If your client is looking for a visually engaging sign, this may be the right customization.

Ideal for: Acrylic, polystyrene, and ACM

Effect varnish

Effect varnish, or spot varnish, selectively applies clear, transparent varnish to certain areas of a print to enhance visual and tactile effects. This technique can highlight specific design elements, create glossy or matte finishes, and even create 3D effects. It can make your client’s design stand out, add a touch of luxury, and create a unique and memorable visual experience. Using a spot varnish, you can take the sign from basic to memorable with applications that replicate effects such as leather, water, condensation, gloss, or matte finishes.

Ideal for: Acrylic, polystyrene, and ACM

Lenticular magnification effect

A lenticular magnification effect is the process of directly printing an image on the second surface (back) of a transparent substrate and following up by printing microscopic, clear, resin-like droplets onto the substrate’s front, which act as tiny magnifying glasses, creating a 3D, visual-depth effect. The printed lenses can cover the entire surface or specific areas of the substrate. Lenticular magnification creates an optical illusion and can add movement to your signage.

Ideal for: Acrylic

Flame polishing

You can enhance the final look of your high-end acrylic signage by flame polishing the edges. By applying a blow torch to the edge of your acrylic, you can melt the surface of cut marks, resulting in a glassy finish that matches the front and back of your acrylic, as opposed to the milky white effect that is created on the edge of acrylic when cut.

Ideal for: Acrylic

Heat bending

You can heat your substrate and hand-bend it to the desired angle using an induction coil. This can create a robust sign that fills the space and offers a 360-degree visual.

Ideal for: Acrylic and polystyrene

Double-sided printing

This method can be used for standard printing functions or to create impressive signage. By perfectly aligning the images on the front and back of the acrylic and making slight modifications to the images, you can create a bold and eye-catching effect.

Ideal for: Acrylic, polystyrene, and ACM

Creating a sign allows you to help your client tell a story and honour their brand. Although this is just a small window into the vast world of signage possibilities, exploring various signage styles can help you enhance your client’s brand visibility and impact—especially when clients come to you with a blank slate, open to ideas and looking for guidance. Consider how different designs, materials, and placements can be utilized to ensure your client’s signage aligns with their business goals and effectively communicates their message.

Shelbi Grove leads marketing at Burke Group, an Alberta-based printing and signage company that blends art, technology, and commerce to provide comprehensive communication solutions, from design to delivery.