From prep to protection: How to wrap a car in the winter

A step-by-step guide to wrapping a car with PPF

Overview

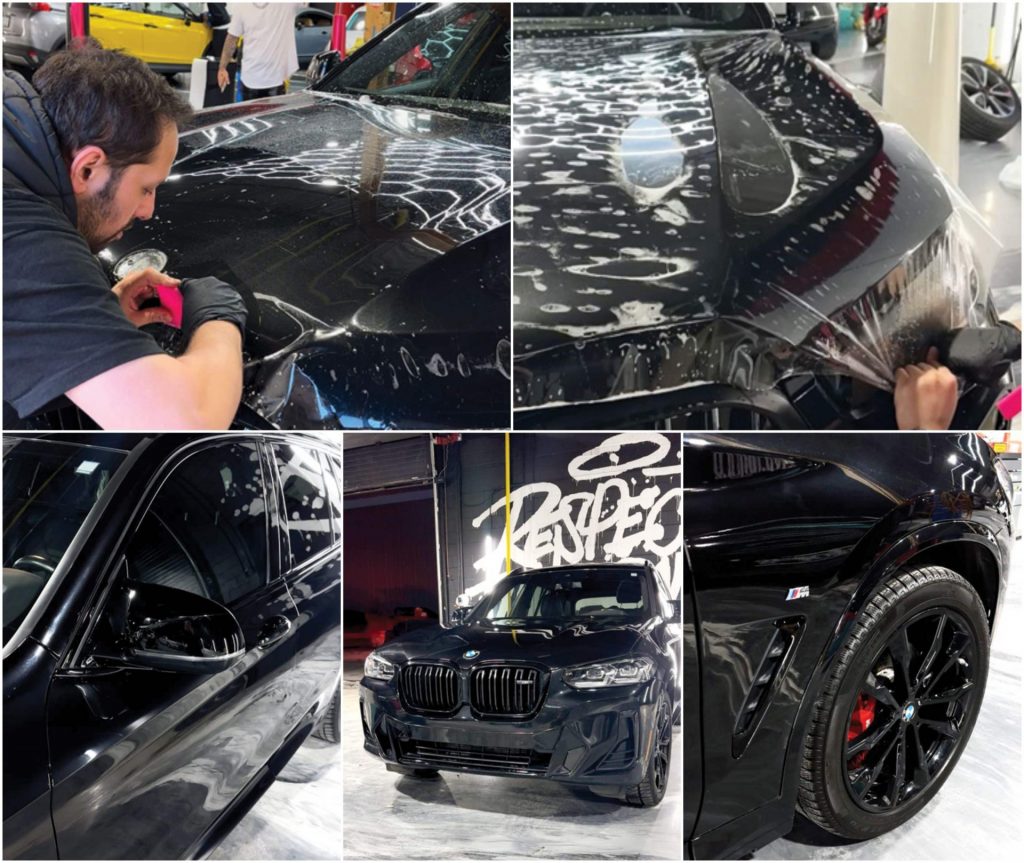

Wraptors HQ in Mississauga, Ont., recently worked with Sean Tullo, owner of Tullo Electronic Services and Repairs, on a full paint protection film (PPF) package for his fully loaded 2024 BMW X3.

Project

The power of online reviews played a crucial role in landing this project. Tullo, who prioritizes thorough research before choosing a service provider, explored multiple options in the area before selecting Wraptors HQ. He expressed that he relies heavily on honest customer feedback, and the strong reputation of Wraptors Toronto on Google Reviews influenced his decision.

Timeline

The complete PPF installation process was completed between January 15 and January 18, 2025.

Scope

The project involved wrapping a black-on-black 2024 BMW X3 with PPF using 16.4 m (18 yards) of material. Since the shop’s expert installer preferred a custom-fit approach, no pre-cut panels were used. Instead, the entire process was executed in-house, with the film being cut and applied specifically to the vehicle’s contours.

Preparation

One of the major challenges of working on vehicles during Canadian winters is ensuring a clean and properly prepped surface. Salty winter roads make it difficult to prep PPF and ensure it adheres properly. To combat this, the team extensively cleaned the car, treated it with a clay bar, wiped it down, and dried it thoroughly before wrapping. This extra step extends the overall project timeline in the winter months but is crucial to achieving a flawless finish.

Materials and tools

To ensure the highest quality installation, the following materials and tools were used:

- Soapy water (filled with our “magic solution”)

- Steamer with distilled water

- Knives and blades

- Special squeegees

- 16.4 m (18 yards) of Xpel Gloss PPF

Steps

The installation process was executed meticulously, following these steps:

- Thorough wash: Using Wraptors No.9 car shampoo with a foam cannon and pressure washer

- Clay bar treatment: Ensuring the exterior body panels are free from contaminants

- Second rinse and wash: To remove any remaining residue

- Drying and surface preparation: Using clean microfibre cloths and alcohol

- Custom panel cutting: Measuring and cutting PPF by hand for a precise fit

- The application process included:

○ Spraying soapy water onto the surface

○ Applying the PPF vinyl

○ Using a steamer to soften and shape the film around corners and edges while allowing the material to relax

○ Squeegeeing out excess water for a perfect seal

○ Trimming edges and corners with a knife for a uniform finish

- Final touches:

○ Apply a light post-heating treatment for added durability.

○ Full vehicle wipe-down

○ Installing a Wraptors license plate frame and air freshener to give it a personal touch

Mostafa (MOMO) Darabi, a PPF specialist at Wraptors HQ, carried out the installation.

Conclusion

This project illustrates Wraptors HQ’s expertise in high-end vehicle protection. By leveraging detailed prep work, premium materials, and precision installation techniques, the team ensured Sean Tullo’s 2024 BMW X3 remains protected against the Canadian elements while maintaining its sleek, showroom-quality appearance. The combination of meticulous attention to detail and the use of top-tier products safeguards the vehicle and enhances its appeal. Tullo can now enjoy peace of mind, knowing he has well-protected his investment.

Matthew Lavery, a brand representative at Wraptors Inc. Toronto, brings 19 years of experience to the sign industry. His extensive expertise and influential presence have made him a respected authority in the field. Wraptors is a global brand with 16 locations worldwide, specializing in vehicle wrapping, PPF, ceramic coating, window tinting, and custom automotive services.