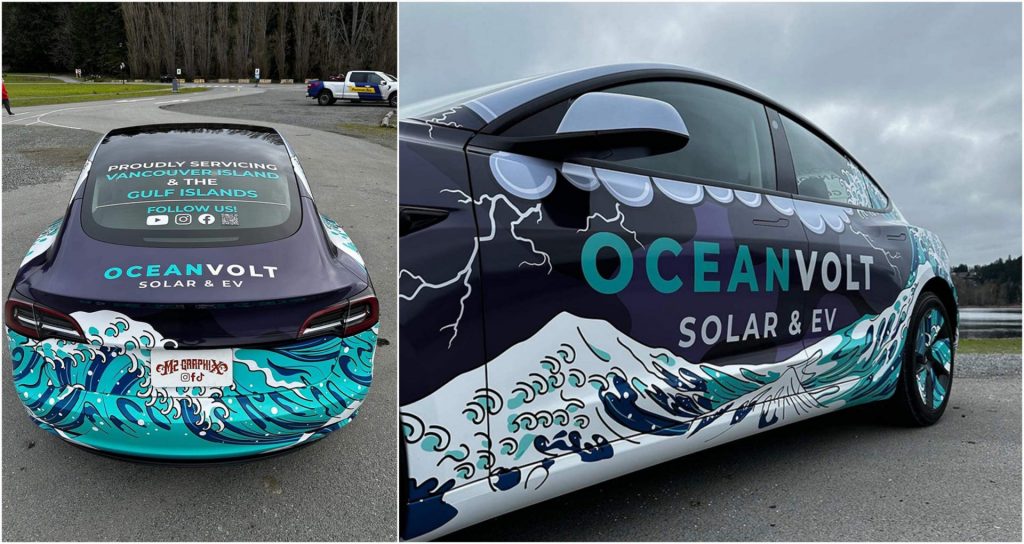

Making waves: A high voltage wrap for Ocean Volt

When Ocean Volt Solar + EV approached us with their newly acquired Tesla Model S, we knew this wasn’t just another vehicle wrap; it was the next chapter in a creative collaboration growing since 2021. Ocean Volt—a locally owned electrical company founded in 2020 by two passionate master electricians—specializes in rooftop solar and EV charging installations. Their fleet is an extension of their brand, and this project was all about building on that visual identity.

Tight circuit

We’ve worked with Ocean Volt since their early days, starting with spot graphics—door logos, service lists, and contact info—on their trucks and decals for their installation equipment. In 2022, we wrapped their cargo trailer—our first full wrap for them—and the relationship has continued to grow ever since.

Fast track

This project kicked off in early May 2025, when they let us know they had just purchased a new Tesla Model S. They were excited to match it to the Tesla Model 3 we had wrapped in 2024, continuing their evolving fleet branding. We completed the wrap during the third week of June.

Riding the wave

The scope of the job was a full commercial vehicle wrap for the Model S, designed to complement their existing fleet lineup: the Model 3, a Mercedes Sprinter, and the cargo trailer. When we began working with Ocean Volt, their logo was an illustrated bitmap. Before wrapping the trailer, we vectorized it to ensure consistency and longevity. Their circular logo is inspired by The Great Wave off Kanagawa by Hokusai (1831), and to expand on that theme, we digitally illustrated more of the wave scene—adding depth, ocean, and sky—all drawn by hand by our lead graphic designer.

All systems go

The wrap design consists of a full, gloss-laminated background print, with the wave and clouds applied to the second surface (also gloss). Lightning bolts and all logos are second surface as well, but printed on 3M 680CR reflective vinyl, creating a dramatic effect when struck by light. From concept to execution, we did everything in-house. The client’s original idea for the trailer wrap was simply: “a full wrap featuring the wave in our logo as large as possible.” We ran with that idea and carried it across their fleet. We suggested adding the reflective lightning bolts and text, and the client loved the effect.

Print, peel, power

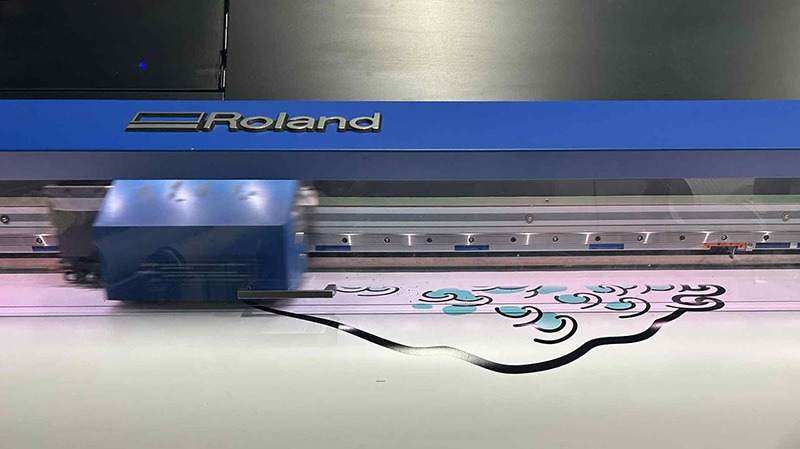

We used a Roland TrueVIS VF2-640 eco-solvent printer to fabricate the graphics. The base wrap was printed on 60” Avery 1105 with 1360 gloss laminate, applied as one seamless horizontal piece, and installed as a single sheet rather than being panelled per door or quarter panel. The lightning bolts were printed on 3M 680CR reflective vehicle-grade vinyl with air egress, while second surface elements like the wave and clouds were printed on Avery 1105 with 1360 gloss laminate. The wave is a continuous print-cut panel running from the front wheel well to the rear bumper. On the bumper, the lower water portion is a separate piece, and the upper wave portion on the trunk is applied as a second surface. We precision-cut all second surface graphics on our Roland GR2-640 plotter.

Bumper to bumper

One of the more complex challenges we encountered was aligning the wave graphic across the rear bumper panel—an oft no-go area for detailed designs. This required creative problem-solving from our lead designer and close collaboration with our install team. We held multiple team meetings, took detailed measurements, printed backup sections just in case, and even created optional overlay pieces to correct any potential misalignment—but we didn’t end up needing any of them.

Sticking the landing

Installation began with a full wash by our detailing team and overnight drying in our shop to ensure it was ready the next morning. The install team prepped the Model S by removing badges, trim, and lights before thoroughly cleaning and degreasing all surfaces with isopropyl alcohol. We used Knifeless tape to apply the graphics and ensure precision seams, followed by a thorough post-heat treatment. The client also requested a “chrome delete” (wrapping all chrome in either gloss or satin black—gloss suited this design best), which we completed as the final step.

This was a fun and creatively rewarding project, and we’re grateful to Ocean Volt for continuing to put their trust in us. We love opportunities to flex our creative muscles with complex, visually striking designs—and we’re always excited to take on more projects like this in the future.

Mike Merryweather is the founder and owner of M2 Graphix, a Langford, B.C.-based vehicle wrap company known for its innovation and quality. With a degree in graphic design and 3D animation and multiple vinyl installation certifications, Merryweather brings decades of experience in branding, logo design, print, and vinyl application to the sign and wrap industry.