Signmakers, level up with 3D printing

Over the past decade, 3D printing has evolved from a niche prototyping technology into a versatile manufacturing tool used across industries, from aerospace to dentistry. Advances in this technology have unlocked its use for new applications.

Curiously, the signage industry has been slow in adopting this technology. Most sign shops still rely on traditional methods such as aluminum bending and plastic trim caps to fabricate channel letters. The scepticism is understandable as signage demands clean finishes, material strength, and durability—areas in which 3D printing once fell short.

However, such concerns are no longer relevant as advances in technology have eliminated these limitations. New materials like polyethylene terephthalate glycol (PETG) and acrylonitrile styrene acrylate (ASA) offer great durability and strength. Advanced slicing software enables fast print speeds. Also, innovative signmakers are finding that 3D printing can be more than a tool for prototyping—it is becoming a viable method for full production, particularly of channel letters.

It is clear that 3D printing can be a valuable manufacturing option for signmakers, especially in producing channel letters. Let us take a closer look at the benefits, challenges of 3D printing and its prospects in the industry.

Why the hesitation?

While many sign shops currently utilize 3D printers, their use is mainly confined to support tasks. Printers are often used to create fabrication aids, like custom jigs, mounting spacers, fastener covers, or LED holders. These tasks benefit from the speed and flexibility of 3D printing, especially when dealing with non-standard designs.

Shops also use 3D printing for rapid prototyping. For example, a design team might print a scale model of a sign for client approval before committing to full production. The ability to iterate quickly with low material cost makes 3D printing a natural fit for early-stage concept validation.

When it comes to actual sign fabrication, very few shops use 3D printing for production. The reason is simple: traditional fabrication methods are familiar, well-supported, tested, and scalable. Additionally, the sign industry associates 3D printing with hobbyists, and its plastic products are considered fragile compared to commercial-grade signage. This perception has also hindered its potential growth within the industry.

While full 3D printing manufacturing adoption is rare in the sign industry, the foundation is being laid for such a future—and many shops are well-positioned to start leveraging this technology.

3D printing and channel letters

Channel letters, typically made with aluminum returns and acrylic faces, are a staple of commercial signage. But their fabrication is labour-intensive, equipment-heavy, and often requires multiple steps involving forming, fastening, and painting. This is where 3D printing is making an impact.

The trend was first observed among Chinese manufacturers around 2019-20. A few original equipment manufacturers (OEMs) introduced printers and software solutions specifically for producing PETG-based channel letter returns. These software programs were designed to minimize the 3D modelling of the part, with simple presets to generate 3D models from vector files automatically. Additionally, the machines are equipped with large print beds, allowing for the production of bigger letters and logos. These innovations reduced fabrication steps, labour time, and material waste.

In North America, adoption has been slower, but there was some early movement. For example, Ascent Equipment and G2G Lighting were among the first North American suppliers to publicly venture into 3D printed channel letters around 2021.

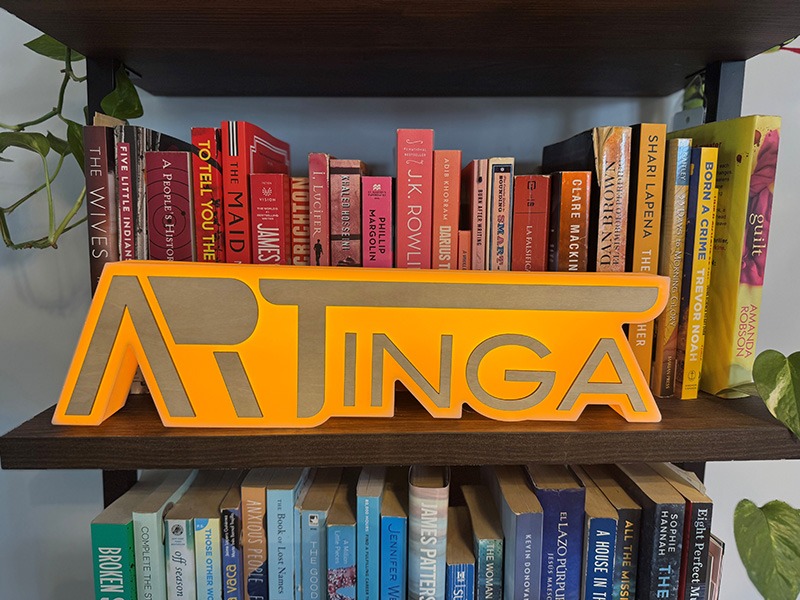

Closer to home, Artinga, a Toronto-based sign shop, has adopted 3D printing to produce indoor channel letters for trade shows, event signage, and retail displays. The company has used industrial-scale 3D printers, such as fused deposition modelling (FDM) printers, that are paired with a CO2 laser cutter, allowing them to produce high-quality visual output. This suggests that the technology is becoming an accessible tool for small-scale, local sign shops as well.

Benefits of 3D printing channel letters

Cost efficiency: Traditional channel letters often require aluminum coil, acrylic sheets, and paint, with prices fluctuating based on supplier and market demand. In contrast, 3D printed returns typically use PETG filament. For example, printing a 50.8 mm (2 in.) deep by 355.6 mm (14 in.) tall letter would cost approximately Cdn$3 in material. PETG is strong, UV-resistant, and available in a range of colours, eliminating the need for painting in many cases.

Additionally, because the returns and face edges can be 3D printed in one pass with integrated design features, there is less need for finishing steps like sanding or priming. For budget-sensitive projects, there is potential for significant material and process savings.

Labour savings: Manual bending of aluminum returns is labour-intensive and error-prone, especially for small or complex shapes. Even with the use of channel letter benders, final forming and finishing require manual handling in many cases, adding time and requiring the presence of skilled labourers.

3D printed returns, however, are printed to the exact shape of the face, eliminating bending entirely. Once printed, they can be bonded directly to the acrylic face using common adhesives. The precision fit removes the need for clamps, magnets, or additional fasteners during curing.

Furthermore, it is possible to print the entire letter, including the face, as a single piece. While this takes longer to print, it eliminates assembly as a step and enables printing designs on the face of the letter or logo.

Design flexibility: 3D printing opens up new design possibilities that are difficult or impossible with traditional methods, such as:

- Intricate letter shapes with internal cutouts

- Compound curves or dimensional embellishments

- Very small letters with high precision

- Translucent filament for side-glow or edge-lit effects

- Irregular returns with angles or bends

- Design patterned faces

With the process being layer-based, there are virtually no limitations on geometry. This makes it ideal for creative signage, unique fonts, or experimental lighting.

Weight: PETG-based letters are 40–60 per cent lighter than equivalent aluminum/acrylic combinations. This makes them easier to ship and less likely to incur damage during transport. For mobile signage, trade shows, pop-up booths, or stage design, this reduced weight is a major advantage.

Additionally, lighter signage can be mounted on surfaces where heavier signage is not an option, such as tensioned fabric walls, thin drywall partitions, or light structures.

Equipment price: One of the most appealing aspects of 3D printing for signmakers is the relatively low barrier to entry. Compared to traditional sign-making machinery, 3D printers are significantly more affordable.

Where 3D printing excels

One thing is certain: 3D printed signage is not a replacement for all sign fabrication. However, it excels in particular niches and is well-suited to indoor or temporary signage. The technology is best utilized for

- Trade show booths

- Seasonal retail campaigns

- Pop-up shops

- Indoor decorative signage

These applications often prioritize speed, portability, and budget—areas where 3D printing shines. The lower material costs, minimal finishing steps, and lighter weight perfectly align with these requirements.

3D printing also appeals to design-forward or experimental projects because the technology allows for creative geometries and translucent materials. It also enables lighting effects or brand esthetics that are difficult to replicate conventionally.

Challenges and considerations

There are limitations. For permanent outdoor installations, especially those exposed to UV, moisture, or impact, most desktop-printed PETG letters still fall short compared to aluminum.

While 3D printing offers advantages, it’s not plug-and-play. Shops considering adoption should factor in the following challenges.

Initial investment: A reliable FDM printer capable of printing signage-grade PETG costs between Cdn$1000 and Cdn$15,000, depending on build volume and quality. Large-format printers are recommended for full letters.

Material quality: Not all filaments are created equal. Low-grade PETG can lead to weak layers, poor surface quality, and unreliable adhesion. Therefore, reputable suppliers are essential to achieve high-quality results.

Underwriters Laboratories (UL) and Canadian Standards Association (CSA) certification: Safety and standards certifications are not yet available for 3D printed signs. UL-certified 3D printing filament is expected to be available within the next couple of years.

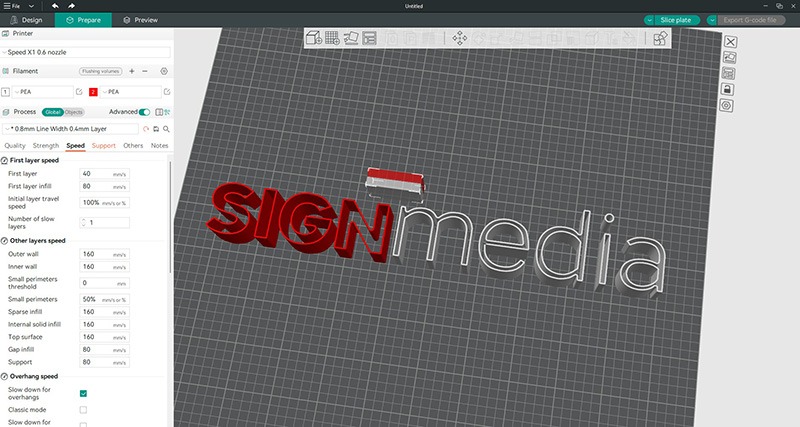

Learning curve: While there is certainly a learning curve, the process is surprisingly intuitive. Most sign professionals already have experience with vector files, material properties, and basic design software. All these skills translate well to 3D printing workflows. With just a few test prints and material trials, it is possible to start producing functional and even client-ready parts.

Looking ahead

While there is still resistance to this technology, trends point to broader adoption of 3D printing in signage over the next five years. Interest is growing at trade shows, on forums, and in design studios, making signmakers evaluate whether this technology fits their productions.

It is unlikely that 3D-printed channel letters will replace traditional signage methods, but they will surely become essential tools.

Getting started: Easier than you think

As stated earlier, 3D printing has a comparatively low barrier to entry, and the equipment footprint is relatively small. Slicing software like PrusaSlicer, Cura, and OrcaSlicer are also free and user-friendly.

Since most sign professionals are already fluent in design software and vector-based workflows, learning the process typically takes only a few hours. Within a few days of setup and testing, a shop could be ready to produce real parts.

Whether you are a boutique studio or a large shop with downtime on the second shift, 3D printing offers a low-risk option with a high-upside opportunity to innovate.

3D printing isn’t here to replace but expand traditional sign manufacturing. As the technology matures and more sign-makers become familiar with its tools, its role in the industry is sure to grow. Those sign shops willing to innovate in 3D printing will find its potential untapped.

With a career in the sign industry since 2018, Gabriel Carro brings technical expertise, hands-on experience, and a deep understanding of computerized equipment in sign manufacturing. As an after-sales and service manager for Ascent Equipment, he specializes in the technical aspects of sign production, providing training and support to industry professionals. He is one of the Canadians recently selected for the 2025 ISA Elite program, recognizing his leadership and contributions to the industry.