Setting standards for colour accuracy and ink consumption

Colour gamut

Colour gamut

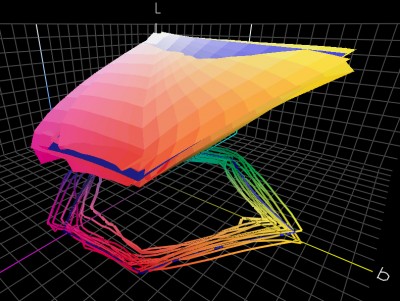

In the preliminary testing phase, Ryerson and IDEAlliance evaluated the colour gamut of 17 wide-format inkjet systems using the American National Standards Institute’s (ANSI’s) standard IT8.7/4 target for colour communications and control specifications. Each device was used to print this target image with 1,617 colour patches to help determine the colour gamut of the whole system, from printer and raster image processor (RIP) to substrate and ink.

IDEAlliance sent each test sheet to Ryerson’s labs, where data was collected to create an International Color Consortium (ICC) profile. From those profiles, each device’s International Commission on Illumination (CIE) L*a*b gamut was compared to GRACoL.

In the image on the right, where the blue area is the GRACoL gamut—i.e. representing commercial offset lithographic printing—it is clear some of the 17 inkjet devices’ gamuts were larger than that of offset printing, while many were smaller. Only three of the systems demonstrated a truly excellent colour gamut.

Colour management

One convenient way to check colour management systems are working correctly is to use a control strip with 54 patches and then measure the results with a spectrophotometer. IDEAlliance used this method for the wide-format inkjet printer testing and compared the measured CIE L*a*b values to the GRACoL target values. In other words, print samples were compared to their intended appearance.

‘Delta E’ is the CIE metric for the difference between two colours. The lower the number, the closer the two colours, meaning the colour is printed as expected, matching the sample or proof that was supplied.

The preliminary testing demonstrated that many of the wide-format systems achieved a Delta E of less than four. Some were even less than two, which put them in the realm of certified colour-accurate proofing systems.

Earlier this year, it is worth mentioning, at the International Sign Association’s (ISA’s) International Sign Expo in Las Vegas, Nev., colour management software was demonstrated with print standard verifiers, which can be used to confirm a print’s conformity to any chosen data set, such as GRACoL, SWOP or the standards established by Fogra, a German research institute for the graphic arts.

This automatic testing procedure can verify a printer’s colour management system is working as intended, which in turn implies the ICC profiles accurately reflect the colour characteristics of the printing system. In other words, IDEAlliance and Ryerson’s recent testing could now be carried out by users themselves.

It may also be important to check colour management systems to prove to customers their graphics are being printed to specified colour tolerances. This type of verification is a way for a sign shop to explain it has the appropriate ICC profiles and can apply them within a system to print colours accurately, in accordance with the chosen data set. Besides GRACoL, there could be other standards the signmaker wants to match, such as an in-house standard or a customer-specific colour setting.

Ink consumption

Quantifying the ink consumption of a wide-format inkjet printer is very complex, as inks are used in many different ways. Ink purging and maintenance practices, for example, help keep the nozzles open and flowing freely during printing.

Some ink may spray or mist, as well, and be lost due to evaporation. And ink may be moved from its cartridge or pouch into an on-board reservoir for future use. So, ink is consumed in many ways that do not involve printing it onto a substrate.

Further complicating matters, some printers use ink sets that include cyan, light cyan, magenta and light magenta, while others use greyscale variable drop sizes. Each of these systems, then, entails a different metric for ink consumption.

One way to monitor ink use, however, is to add a software-based reporting system. This type of technology was also showcased earlier this year at ISA’s expo, including G7 calibration, profiling and ink consumption tools that work together to evaluate a printer’s colour quality and performance. The software can even display the cost of the ink used in a given job.