Modernizing installations: A setup for success

The secrets and strategies for seamless sign installations

The signage industry entered 2025 stronger than ever. Over the past two years, more than half of signage businesses have seen steady growth in both sales and profits.

According to a Research and Markets 2024 report, the North American printed Signage Market is steadily growing. Projections show an increase from US$ 12.68 billion in 2023 to US$ 15.93 billion by 2029, reflecting a compound annual growth rate (CAGR) of 3.72 per cent.

Many signage companies are now looking for ways to streamline operations, improve efficiency, and maximize existing resources through automation to keep up with growing demand. For many, the manufacturing process has always been the priority—the part where raw materials are turned into high-quality signs.

While many businesses prioritize cutting-edge technology in manufacturing, ensuring it is always the fastest and highest quality, their installation processes can sometimes remain low-tech. This strategy costs companies valuable revenue opportunities and growth potential, so it may be time to reconsider. How can this be achieved?

A win-win

Signage installation isn’t just another step in the workflow—it is where all the effort poured into planning, design, and manufacturing comes to life and when the customer sees the final result.

To maximize the impact of this crucial step, signage companies need to step away from the mindset of “If it’s working, why fix it?” or “This is how we’ve always done it.” They should recognize the potential to automate traditional workflows and embrace more streamlined installations.

With this approach, sign installation companies can provide top-notch installations and thus drive revenue growth while making work easier for the entire team.

For example, for project managers, streamlining installations means instant access to project updates, status reports, and installers’ feedback. They can provide customers with timely, accurate updates without the need to chase for information from installation managers or wait for photos from installers. Instead, they can resolve potential problems before they escalate and spend the time saved on revenue-generating tasks, such as managing additional projects or supporting existing clients.

Streamlined workflows also allow installation managers to shift their focus from time-consuming administrative tasks to what brings value to customers—solving on-site challenges and ensuring projects are set up to run smoothly. With fewer costly revisits, they have the time to match the right vendors with the right jobs based on skills, location, and schedule.

Whether in-house or external, installation vendors reap the benefits of more streamlined installations, allowing for clear visibility into ongoing and upcoming jobs, helping them minimize delays, and avoiding scheduling confusion.

Overall, streamlining internal processes helps signage companies hit two goals at once: reduce the workload on their team and consistently deliver flawless, on-time installations that exceed customer expectations. Along the way, companies build a stronger brand reputation, strengthen customer trust, and create new growth opportunities—all without having to take on extra resources or new staff.

Real-world examples

Let’s go beyond the theory and look at real-world scenarios that sign and printing companies face when managing their installations and what practical benefits they gain from a more streamlined approach.

Two excellent examples are Composition Systems Inc (CSI) in Alexandria, Va., and Category 5 Imaging in Burlington, Ont. Both provide signage, graphics, and visual displays across North America. Despite a wealth of expertise, their teams found that sticking to the old way of managing installations made it harder to scale and meet the increasing demands of their customers.

CSI recognized that the installation process can be a maze of time-consuming tasks that had to be managed through a combination of several different software systems, taking up valuable time and resources.

While the team used Durst’s Lift ERP system to handle printing, quoting, and invoicing, the installation side of their operations remained disconnected. Installation jobs had to be manually copied from Lift, with team members manually co-ordinating schedules, preparing physical guides, and updating clients on the progress. This workflow led to daily obstacles for the team.

Category 5 faced a different set of challenges and consequences. Their team used a mix of emails, phone calls, text messages, and spreadsheets to manage installations. They primarily worked with external installation service providers, so ensuring smooth coordination was their

top priority.

With dozens of installation projects to complete each week, the lack of a centralized system made it difficult to track progress, resolve issues quickly, and maintain high-quality results. Information scattered across multiple communication channels even led to unwanted delays, impacting customer satisfaction. At one point, the Category 5 team even considered building their own tool to optimize the installation process.

Industry-specific solutions

To improve installation workflows, addressing two critical needs is essential for overcoming the challenges faced by CSI and Category 5: eliminating manual data duplication and replacing multiple communication channels with one central space for teams to collaborate.

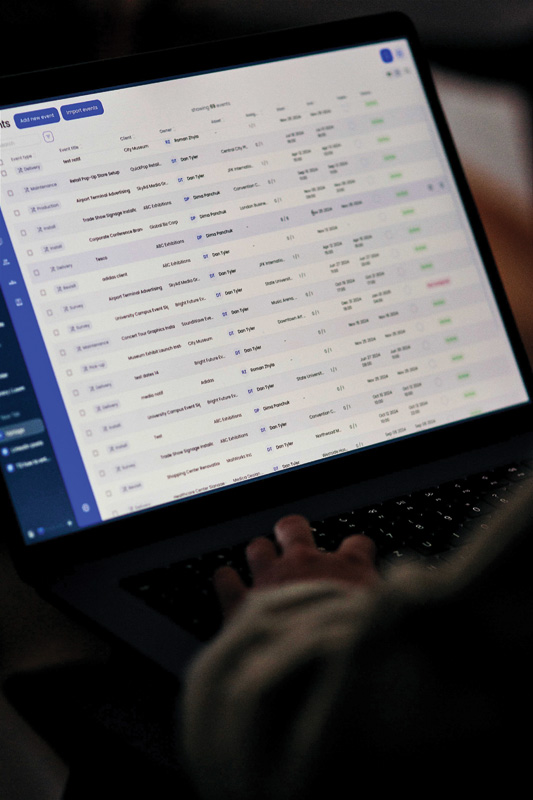

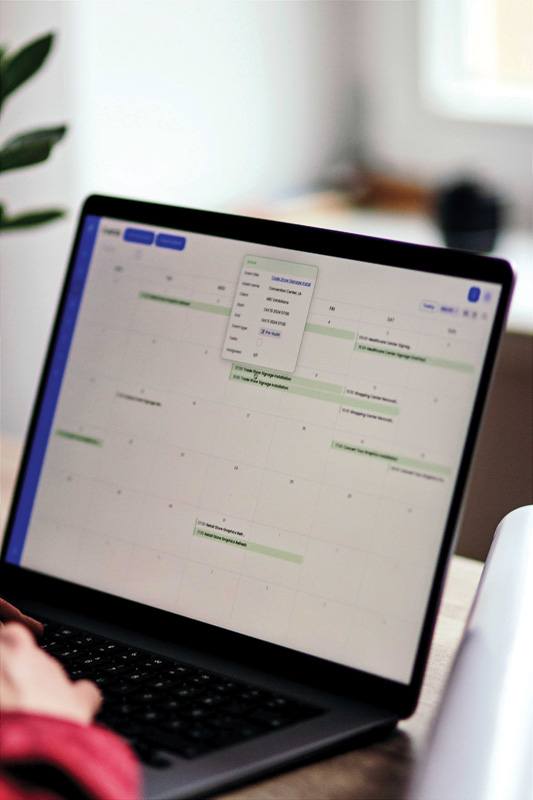

One solution is utilizing an installation management software tool. By automating repetitive tasks and bringing together disconnected teams, installation management software can help teams like CSI and Category 5 handle installations more efficiently.

For example, installation management software Vantage (explicitly created for the wide-format printing and signage industry) integrated with Lift ERP, connects production and installation for CSI, reducing paperwork and the possibility of human error. Installation campaigns are automatically imported from Lift, and progress is synced across both systems in near real-time. This saves the CSI team more than 10 hours each week on scheduling alone and helps them easily manage five to 15 installations daily and even more in peak periods.

For Category 5, Vantage organizes all installation details in one place. This allows project managers to quickly check installers’ availability, track ongoing jobs, and schedule work more efficiently. This cuts down admin phone calls and manual follow-ups, saving the team more than 40 hours a week—time they now dedicate to working on other projects.

The journey to installation efficiency

The CSI and Category 5 cases illustrate that signage companies are often aware of issues with their installations but may not fully understand the potential savings that could be achieved by streamlining their installation processes.

If this resonates with your business and you’re uncertain about how to improve workflow without overwhelming your team, now is an excellent time to set goals for streamlining installations. Take a moment to reflect on what you aim to achieve and establish realistic objectives for these improvements.

Is streamlining installation a priority for you? To find out, follow these steps:

First, discuss with your team and any third-party installers you work with to identify gaps in your current installation workflow. This exercise will reveal areas where time is wasted on repetitive tasks, money is lost due to simple mistakes, and productivity is affected by unplanned downtime and inefficient processes. While some issues may be obvious, you might also uncover surprising insights that could lead to quick fixes or opportunities to add value for your customers. The areas you identify will represent growth opportunities for your company, and the good news is that modern software solutions and automation can effectively address many of these challenges.

Second, automate everything that can be automated. When changes occur in the system, project managers shouldn’t need to make multiple phone calls or send numerous emails to inform everyone involved. Ideally, your system should automatically notify the right people that something has changed, allowing them to reach out for any issues. This automation frees you to concentrate on tasks that add value, such as troubleshooting on-site issues, solving complex installation challenges, or collaborating with project managers and customers to find the best solutions for upcoming jobs.

Third, when seeking solutions to streamline your installations, avoid one-size-fits-all tools that attempt to serve every industry. Instead, choose software specifically designed for print and signage companies. Industry-specific tools are tailored to address your business’s unique challenges and can seamlessly integrate with other systems. In contrast, generalist software tries to cater to everyone, often falling short in features that can save you time in your industry.

Finally, having a clear understanding of your end goals is crucial. With a thorough knowledge of your current installation workflow management processes, take some time to evaluate best practices within the industry and even globally. Use this information to define what success looks like for your business. Is it about achieving greater efficiencies, enhancing customer relationships, or simply making work more enjoyable for your team?

Installation is the step that transforms all your work into tangible results. Don’t let it be an afterthought.

Roksoliana Sydorksa is product and operations lead at Vantage, an installation management software built for signage and print companies. Learn more at www.vantage.software.