Installation equipment: Safely lifting the sign industry

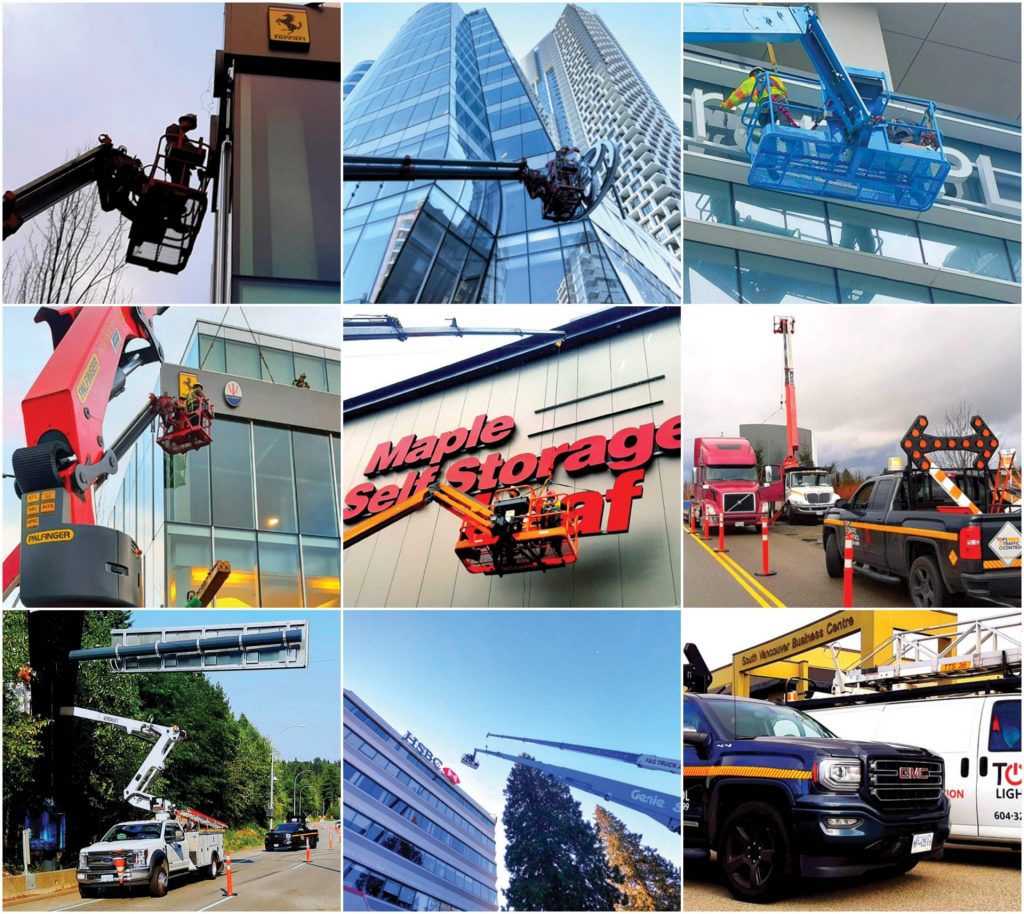

Cranes and boom lifts have revolutionized the sign industry, making it safer, more efficient, and capable of handling increasingly complex projects. As businesses demand larger signs in more challenging areas, these machines provide the reach, stability, and precision required to get the job done right. From hoisting massive, illuminated channel letters onto high-rises to servicing towering pylon signs, cranes and lifts are the backbone of modern sign installation and maintenance.

Beyond their practicality, these machines are essential for job site safety. Traditional scaffolding and ladders have inherent risks, but boom lifts offer a stable, controlled platform with designated safety harness attachment points, reducing the chance of falls. Cranes, meanwhile, take on the heavy lifting, preventing injuries caused by manual handling of oversized sign components. Combined with skilled operators, the result is a smooth installation process that meets the highest industry standards.

As the demand for bigger and bolder signage grows, cranes and boom lifts will remain indispensable tools. However, because these machines operate at heights and in challenging conditions, regular inspection, maintenance, and compliance with safety standards are essential. Safety protocols go beyond just ensuring the equipment functions properly—they also ensure that sign installers using them are trained, certified, and compliant with industry regulations. Adhering to prescribed Canadian safety standards, workplace safety codes, and mandatory training programs helps minimize risks, protect workers, and maintain smooth project execution.

Planning

Before any crane or lift goes into action, safety comes first—every time.

This begins with ensuring all operators receive comprehensive training, covering everything from hands-on equipment use to emergency procedures and risk assessment. Skilled, knowledgeable operators are essential for safe job execution.

Operator training is just the starting point. Sign installation involves layers of protection at every stage to keep everyone and every piece of equipment safe throughout the process. Protecting workers, the public, and the signage itself requires careful planning. Workers must be trained in fall protection, certified in boom lifts, scissor lifts, and crane operations where required, and have hands-on experience in hazard assessment and mitigation. Every factor must be assessed, including ground stability, overhead hazards, lifting radius, and traffic interference. In Ontario, sign installers must complete Chief Prevention Officer (CPO)-approved “working at heights” training when using fall protection systems. Under the Occupational Health and Safety Act (OHSA), this training is mandatory for those using travel restraint systems, fall arrest systems, safety nets, and work belts. Certification is valid for three years through an approved provider.

Additionally, obtaining the necessary permits and adhering to regional standards is critical to the planning process. An example is the Canadian Electrical Code (CEC), which mandates that electrical contractors (or others responsible for the work) must obtain a permit from the inspection department before installing, modifying, repairing, or extending any electrical equipment used in signs.

Inspecting

Keeping equipment in top shape is a necessity. Boom lifts, cranes, and their integral components require thorough annual inspections. Daily inspections before use and checks after any extended downtime are essential for catching potential issues before they become hazards.

Installation inspections don’t stop there. During installations, inspectors verify proper mounting, structural integrity, and electrical connections, where applicable. For inground signs, a pre-pour inspection may be required to assess the support structure before concrete is poured. After installation, a final inspection confirms compliance with approved plans.

Documenting

If it’s not documented, did it happen?

Every inspection must be properly recorded and easily accessible. In the sign world, documentation isn’t just paperwork; it is proof. Every step must be recorded, whether a basic harness and lanyard inspection, detailed work instructions, emergency procedures, hazard assessments, or a full lift plan. Just like your math teacher always told you to “show your work,” breaking down each step and explaining the process behind your solution is essential.

Proper documentation is also about accountability, preparedness, and ensuring every team member knows the plan. When workers have access to clear protocols and job reviews, they understand exactly what to expect and how to proceed safely. A well-informed crew leads to reduced risks, improved proficiency, and smoother project execution. Safety isn’t merely a checkbox on a list—it is an ongoing commitment, and thorough documentation is the essential tool that ensures it remains a top priority in every aspect of the work.

Zoning

Create a clearly defined work zone.

Establishing a secure perimeter keeps both workers and the public out of harm’s way, preventing accidents before they happen. Safety isn’t just about the lift itself; it’s about maintaining control over the entire job site.

Keep your eyes on the sky as the weather can change in an instant, turning a routine lift into a high-risk situation. Strong winds don’t just shift loads; they can make them feel heavier and harder to control. Lightning in the area is a clear sign to reassess whether it is safe to continue. Rain can quickly turn stable footing into an unpredictable hazard. Adaptability is key because, in this industry, the safest lift is the one that takes every element into account.

Futureproofing

Crane technology has advanced rapidly, allowing us to monitor job sites remotely, track equipment performance, and even detect if weight capacities or range limits have been exceeded in real-time. These innovations are making the sign industry smarter and safer than ever before. Sign installers must understand these advancements and operate these machines easily and well.

The sign installation industry is evolving with several key innovations. These include electric and alternative fuel vehicles, greater cellular data connectivity, which will enhance real-time data and improved communication to boost efficiency and co-ordination, and artificial intelligence (AI), which will further expand automated tasks in the realm of installation, helping businesses make data-driven decisions. Understanding and adopting these technologies will elevate safety, productivity, and sustainability in the industry.

The future of sign installation is evolving fast, and these innovations will transform the industry. One thing is certain: the next big breakthrough is just around the corner, and it will elevate safety and productivity in the industry to new heights.

Kenn Leech is a senior sign technician/health, safety, and environment (HSE) representative for Tops Lighting Sign Installation & Services, working out of Ottawa, Ont. Leech is also the traffic manager for Tops Traffic Control, Canada’s first sign industry dedicated traffic services company.