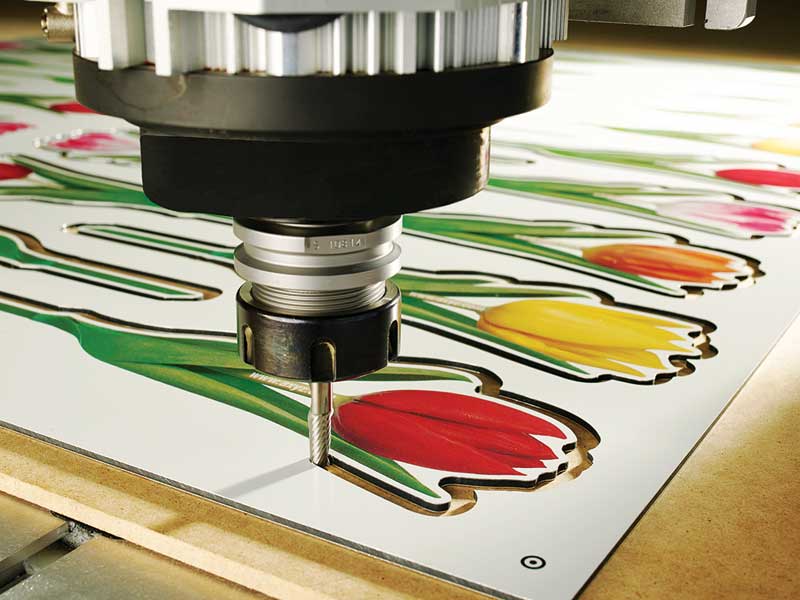

Finishing: The importance of CNC router maintenance

A detailed schedule

Each CNC router is accompanied by the manufacturer’s guide for daily and weekly preventive maintenance, including inspection forms, times for logging operating hours, general cleaning steps, air pressure readings and guidelines for oiling the oscillating knife, checking the pump oil and cleaning the cover nut threads.

Monthly inspection forms, meanwhile, will cover greasing of racks, pinions and bearings, vacuum table gasket repairs—if needed—and cleaning of all filters.

Finally, a form for biannual maintenance inspections will address the replacement of all filters, the testing and inspection of vacuum performance and the tightening of all timing belts and transmissions.

Beyond the checklist

Signmakers who use CNC routers have also learned there are times when a checklist is not enough to ensure smooth operations. Much like a vehicle, if the router does not sound just right, then additional analysis is necessary, even in cases where all of the checklist steps have been completed in a timely fashion.

The emphasis on preventive maintenance should be the same throughout the useful life of the machine as it was at the beginning. Users will need a cleaning procedure and must make sure to remove every tool in the spindle.

It is the shop owner’s responsibility to make sure his/her workforce clearly understands any shortcuts will be counterproductive and ultimately costly to the business. While routers are designed with long-term use in mind, they can quickly fail if any maintenance procedures are circumvented.

The possibility of failure can also be due to other causes, such as improper operational procedures (e.g. when tools break because the right setup was not implemented) or when the machine’s movement is obstructed (which increases wear and tear and inevitably shortens its lifespan).

The best way to ensure lengthy, productive CNC router operations and to reap the full benefits of the machine’s capabilities is to follow the manufacturer’s maintenance recommendations, but it may also be worthwhile to consider other service packages that are offered by the same manufacturer. This is because all machines, regardless of their sophistication and how thoroughly their maintenance plan is followed, will experience wear and tear over time. And if a machine is idled, then the sign shop is left with an expensive, non-functioning piece of equipment and a drain on its balance sheet.

Noel Archie is product manager for Axyz International, which manufactures CNC routers and knife systems in Burlington, Ont., and maintains application development centres around the world. For more information, contact him at (800) 361-3408 or visit www.axyz.com.