CNC routers: Teaming up with tech

The future of sign making relies on adopting computerized manufacturing

can significantly enhance production. Photos courtesy Gabriel Carro

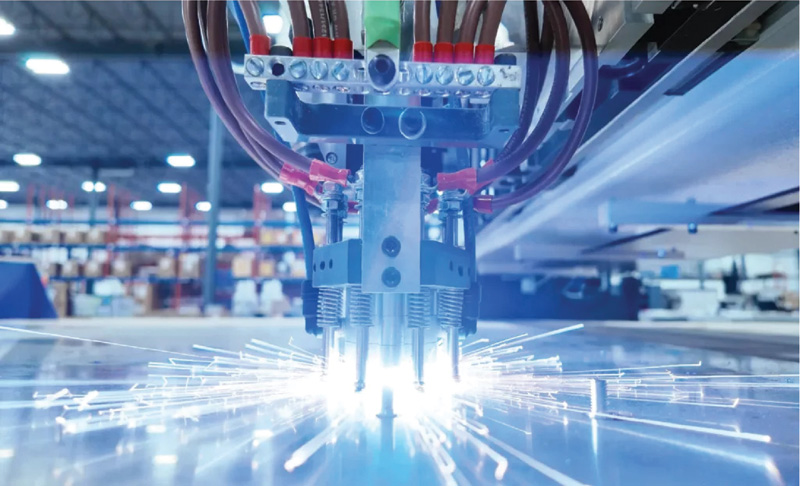

For decades, we have dreamed of a future where machines do all the hard work for us. In the sign industry, that future is here. Computerized machines make sign manufacturing easier and more efficient.

At the heart of this revolution is the computer numerical control (CNC) router, an essential tool in any sign shop. Whether cutting, engraving, or shaping intricate designs, CNC routers complete tasks in minutes that once took hours of manual labour. Their impact is so significant that we will explore their role and capabilities in detail.

But CNC routers aren’t the only game changers. Other computerized machines such as 3D printers, channel benders, and laser cutters are transforming production workflows. These tools enhance efficiency, consistency, and creative possibilities. Successfully integrating them into the manufacturing process is crucial. Without proper adoption, shops risk falling behind in efficiency, productivity, and profitability.

A cornerstone

For most projects, production starts with the CNC router. From cutting letters and logos to shaping designs, these machines are the workhorses of the shop.

Understanding the return on investment (ROI) of a CNC router requires evaluating multiple factors. While precise calculations vary based on shop size, project complexity, and labour costs, key benefits include:

- Labour savings: CNC routers significantly reduce manual labour. While an operator is still required, they can focus on other tasks once the cutting cycle begins, improving overall shop efficiency.

- Precision and material optimization: These machines minimize human error, reducing costly mistakes. Advanced nesting software allows more parts to fit on a single material sheet, reducing waste.

- Expanding capabilities and new revenue streams: Beyond cutting, CNC routers can engrave, carve at different depths, and create intricate designs, opening doors to complex and high-value projects.

Key considerations

Now, not all CNC routers are the same. A shop specializing in indoor signs may not need a large cutting area, while fabricators of large signage will benefit from a bigger machine. The main aspects to consider for a CNC router are:

- Cutting area size: Ensure the CNC router can handle at least 90 per cent of the shop’s projects. Consider the largest material size that will be cut and standard sheet sizes, typically 4 x 8 in. (101.6 x 203.2 mm).

- Spindle power and machine rigidity: Cutting power depends on the spindle and the machine’s structural rigidity. Most machines can handle the materials used in sign manufacturing, but stronger machines ensure smoother operation and better results, especially for aluminum and harder materials.

- Human Machine Interface (HMI): Machines may be controlled via programmable computers (PCs), control panels, or remote handheld devices. The HMI system facilitates communication and control between a human operator and an automated machine or system. PCs are easier to replace but more sensitive to shop conditions.

Software compatibility: CNC routers operate on G-code (a programming language) generated by various software. Some allow real-time control and automatic G-code transfer. A simple interface improves usability, while advanced software is necessary for 3D carving. - Material hold-down methods: Several methods are used to hold down materials during use. These include pressure rollers, clamps, or vacuum tables. Vacuum tables are common but may struggle with small parts due to limited suction surface.

- Debris collection system: CNC routers produce substantial dust and debris, making an efficient dust collector essential.

On top of these key aspects, there are many other technical aspects involved in a CNC machine, and the advancement in technology has enabled the integration of new features that can significantly benefit production, such as:

- Automatic Tool Changer (ATC): This is useful for engraving and multi-tool processes but may be unnecessary for sign shops using one or two tools per job.

- Tool calibration touch probes: Usually included with ATC systems, these probes accurately measure tool depth.

- Cutting tools: Routers now handle drag knives and specialized bits, such as V-bits for engraving or aluminum composite material (ACM) scoring bits for faux neon effects.

- Vision systems: Cameras can align with register marks and material edges for easier, more accurate setup.

- Stud welding: An emerging innovation—as seen in AXYZ PANELBuilder—enables precise stud welding on aluminum panels.1

Additional equipment

While CNC routers are at the core of most sign shops, they are just one piece of the computerized manufacturing puzzle. Other advanced machines, such as channel benders, laser cutters, and 3D printers, enhance efficiency, expand fabrication methods, and unlock new creative possibilities.

Channel benders

Before automation, fabricating channel letters required extensive manual bending and assembly. Channel benders have revolutionized this process by automatically shaping the returns into precise letter profiles, significantly reducing manufacturing time.

More importantly, they have enabled sign shops to adopt new assembly systems, such as glue-based or snap-fit connections. These methods eliminate the need for welding or mechanical fasteners, simplifying the installation and fabrication processes while maintaining durability.

Beyond bending precision, modern channel benders offer new features that further improve efficiency. Some now include automatic output cutters for continuous letter production and integrated punches for drain holes, reducing manual work. Newer models also support a wider range of materials, with increased width and thickness options and a plastic and aluminum trim cap, expanding fabrication possibilities.

Laser cutters

Laser cutters offer unmatched speed and a flawless finish, making them essential for modern sign production. Carbon dioxide (CO2) lasers are used for cutting acrylic, wood, and other nonmetals, while fibre lasers are used for cutting metals like aluminum, steel, and stainless steel.

Beyond cutting, lasers can engrave with high precision. While they have some 3D capabilities, their depth control is limited, making them unsuitable for cutting at various depths.

Advancements in technology have increased laser power, enabling faster cutting speeds and the ability to process thicker materials. Additionally, new hybrid laser cutters integrate CO2 and fibre lasers in a single machine, allowing shops to cut a wide range of materials without switching equipment, maximizing efficiency

and versatility.

3D printers

3D printing is becoming an exciting addition to sign shops, particularly for channel letters, offering lightweight materials, minimal waste, and lower production costs while allowing for unique design customization.

However, material limitations remain a challenge, especially in weather-resistant and flame-retardant options for long-term outdoor use.

- Integrating computerized machinery into the manufacturing process is essential. Without proper adoption, businesses risk losing efficiency, productivity, and profitability.

Manufacturers are developing larger industrial 3D printers specifically for channel letter production to support this growing trend. Additionally, new channel letter-specific software can automatically generate 3D profiles from 2D vector artwork, streamlining the design to the production process and making 3D printing a more viable option for smaller sign shops.

Automated signage

A growing number of automated machines are making their way into sign manufacturing, enhancing efficiency and reducing manual labour. Among them are material sheet loading systems, which streamline material handling, and automatic laser welders, offering precise and consistent welds. Even multi-axis robotic arm cutters are used in sign companies, such as Custom Engineered Arts’ KUKA 7-axis robotic CNC.

Integrating tech

When properly integrated, multiple automated machines work together to create a seamless and highly efficient production process. Shops that adopt these technologies and stay ahead in a competitive market. Those who fail to embrace automation risk falling behind, struggling with slower production, higher costs, and limited manufacturing capabilities.

However, integration is not always easy. Automated machines operate differently, and adjusting production workflows takes time. Once processes are refined, the benefits become apparent, with faster turnarounds, reduced errors, and optimized material use.

Co-ordination between these machines is essential to ensure each sign component fits together correctly. Poorly integrated workflows can lead to mismatched components, rework, and inefficiencies. For example, trimmed faces may not fit properly into the cans when manufacturing channel letters, causing delays and material waste.

Software compatibility also plays a key role. Ensuring machines use compatible file formats can save much time in production.

To ensure success, careful planning, precise machine calibration, and structured production design are essential. Shops that focus on these elements can maximize the efficiency of their equipment, minimize downtime, and improve overall quality. As technology advances, those who embrace a well-co-ordinated, automated workflow will be best positioned for success.

Embracing automation

The sign industry is shifting from a manual craft to advanced, technology-driven manufacturing, with automated equipment transforming production. However, adding new equipment alone is not enough. Successful integration requires planning, calibration, and workflow adjustments. Machines must work in sync to avoid costly errors, like mismatched components or inefficiencies.

Whether adopting your first CNC router or managing multiple machines, analyzing your manufacturing process is key. Understanding your needs helps maximize equipment capabilities and guides smarter investments.

As technology advances, embracing automation is no longer optional; it’s the future of sign manufacturing. Shops that adapt will thrive, while those slow to evolve risk falling behind.

Notes

1 Read more about the AXYZ Stud Welder System here: https://www.axyz.com/blog/the-axyz-stud-welder-system-precision-welding-for-aluminum-cladding/

With a career in the sign industry since 2018, Gabriel Carro brings technical expertise, hands-on experience, and a deep understanding of computerized equipment in sign manufacturing. As an after-sales and service manager for Ascent Equipment, he specializes in the technical aspects of sign production, providing training and support to industry professionals. He is one of the Canadians recently selected for the 2025 ISA Elite program, recognizing his leadership and contributions to the industry. To learn more about CNC routers offered by Ascent Equipment, visit https://www.ascentequipment.com/cnc-routers.