The sustainable signs handbook

Step-by-step strategies for meeting environmental demands in the signs, print, and display industry

Canada’s sign, print, and display industry is already busy: Materials are changing, deadlines are tighter, and client questions are getting sharper. The shift is real. The good news is that sustainability doesn’t have to slow you down or push up costs. Done properly, it sharpens your specs, reduces waste-handling pain, and strengthens your proposals.

The conversation has shifted. Clients are asking about sustainability up front, and sign-makers must be ready with smart, honest answers. What follows is the practical playbook I share with brands, retailers, and manufacturers—cut straight to the realities of fabrication, installation, and removal in 2025.

Follow the leaders—then get a step ahead

One of the clearest drivers of change is the influence of global brands and retailers. Wherever big players go with sustainability, the rest of the world tends to follow. If you want a preview of tomorrow’s briefs, watch what’s appearing in shopfronts, stadiums, grocery chains, and exhibitions today. Those material choices will set expectations for the next tender you see.

In practice, this means two things for Canadian firms:

- Read the room early. If you see a national retailer standardizing on fibre-based substrates for in-store displays, expect that preference to show up in your next request for proposal (RFP)—whether you’re in Vancouver, Calgary, Toronto, or Halifax.

- Align before you’re asked. If you adopt those practices now, you’re ready when procurement teams or local councils start asking tougher questions. Prepared suppliers win work while others scramble.

Materials: know what you’re buying—and why

One of the biggest gaps I see is material knowledge and the information (or lack thereof) accompanying products. Too often, materials are badged with vague labels without any explanation. That doesn’t help anyone.

You don’t need buzzwords; you need specifics:

- What’s the substrate made from? Fibre, plastics, aluminium, composite, metal?

- What are the performance characteristics? Durability, printability, impact resistance, outdoor rating, or their sustainability credentials?

- What happens at the end of life? Can it be reused, mechanically recycled, taken back, or will it end up in mixed waste?

- What are the logistics implications? Weight, packing density, and transport impacts.

If you want clean answers, talk to your suppliers—and talk early. They know the technical details. Ask for data sheets, recovery options in your province, and practical guidance on adhesives, fixings, and coatings that won’t block recycling. That’s the information your clients can trust, and the information that keeps you out of trouble when claims are challenged.

Two quick rules of thumb:

- Lighter usually means smarter for temporary and short-term work—less fuel, easier handling, often better packing density.

- Simpler constructions (single-material where possible) make recovery or recycling far more likely.

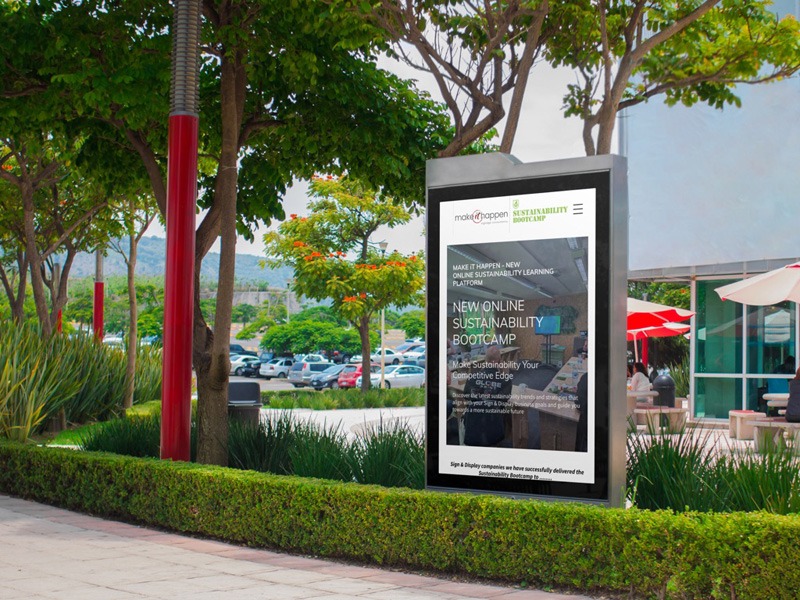

Sustainability training: The overlooked multiplier

For small and mid-sized sign-making businesses, knowing where to start can be daunting. You don’t need a degree; you need a repeatable way to make better decisions on the job ahead of you.

Make time for accessible training and peer learning. Join your local association sessions, attend a webinar, sit on a panel, or set up short internal lunch-and-learns. Training doesn’t have to be formal; it has to be frequent. The goal is shared language and confidence across sales, design, production, and install.

This is vital when trialling new materials. Worries about performance are fair—so test them internally first. Run a quick pilot: Print, route, fix, and remove. Record the lessons. Once you’ve proven what works, you can offer it to customers without risking a live job. Become a quiet hub of innovation. When you’ve validated a new route, your clients feel the benefit—and you bank the margin.

Packaging: Less theatre, more engineering

Packaging is a blind spot that costs more than it should. You can’t ship a premium sign wrapped in brown paper and string; clients expect goods to arrive pristine. But mountains of bubble wrap and polystyrene aren’t the answer either.

Start with fibre-based wraps, paper tapes, honeycomb board, and reusable corner and edge protectors. Many teams are already reusing shredded delivery boxes as void fill for outgoing shipments. That’s fine—if it protects the product and you’re not introducing contamination that fouls recycling streams at the destination.

And yes, legal pressure is building internationally. You don’t need to reference chapter and verse to act. Do the engineering: protect the item with the lightest, most readily recyclable system you can source, and standardize it. The cost savings show up quickly in material usage and skip charges.

Durable metals: Say the whole truth

Aluminium and steel get a bad rap for their production footprint. Tell the whole story. They last. These are not throwaway materials. For frames, trays, totems, and long-life externals, aluminum and steel often offer the best lifetime performance. When they finally reach end-of-life, they’re recyclable at scale. Industry figures often cite that roughly 97 per cent of all steel ever made remains in circulation—the exact number aside, the point stands: durability and recoverability matter.

Use these materials where they make sense. Design them to be unbolted, not smashed. Keep coatings and fixings compatible with recovery routes. That turns a cost centre into value.

From skips to circular design

Most signmakers are more circular than they think. Trays get reused. LED systems are moved to the next location. Brackets and posts have second and third lives. Often, it’s done quietly to save money. Good. Now, formalize it.

- Design for disassembly. Use mechanical fixings instead of “forever adhesives” wherever performance allows. Specify modular components that come apart easily.

- Keep like with like. Single-material backers and panels are far more recoverable than composites glued together for life.

- Write reuse into the brief. If a client regularly updates campaigns, propose a refreshable system with replaceable faces rather than a full rip-and-replace.

With rising skip costs and tighter compliance, the economics will push the industry this way regardless. Get there early and make it an advantage.

Logistics: Lightweighting and smarter routes

Transport is one of the easiest places to find quick wins—especially for large-format and temporary work.

- Lightweighting cuts fuel use and vehicle wear. If the substrate meets performance needs at a lower weight, take it.

- Flat-pack thinking reduces trips. Can the sign or display be shipped as a kit and assembled on-site?

- Routing and consolidation save money immediately. One firm I worked with re-mapped delivery routes and driver schedules; the fuel and time savings paid for the exercise in weeks.

Electrification will scale unevenly for long-haul, but you don’t need to wait for that. Careful planning and design deliver results now.

Stay out of trouble: Avoid greenwashing at all costs!

The biggest reputational risk in sustainability is saying the wrong thing. Words that sound virtuous but mean nothing won’t survive in front of a sceptical client—or a regulator.

Here’s the safe path:

- Be specific. “Fibre-based display using a single-material backer and mechanical fixings; designed for disassembly; recovery route confirmed with [local recycler].”

- Source your facts. Use product data sheets and supplier statements you can show on request.

- Never over-claim. If the route is “technically recyclable” but no local facility will take it, say so—and offer a real alternative.

- Keep records. Store specs, photos, and recovery confirmations. When procurement asks for proof, you have it.

Internationally, penalties for misleading environmental claims are real and growing. You don’t need fear to act; just run a professional process that would stand up to scrutiny.

What will change fastest?

Over the next five years, expect the quickest shifts in temporary signage and internal displays. Fibre-based and hybrid materials are already replacing plastics in many applications. We’re seeing better moisture resistance and strength without the disposal headaches.

Internal retail and events will likely evolve faster than externals. You’ll still need the right substrate for the job, but the range of viable, lighter-impact options will continue to expand.

For permanent signage, change will be steadier—improvements in LED efficiency, power control, and material lifespan rather than dramatic substrate swaps. Treat these as whole-life projects: serviceable, upgradeable, and easy to refresh without a full rebuild.

Where durable metals and modern fibres meet

There’s no single “best” material. There are better choices for the job at hand. For a permanent external sign, aluminium or steel—designed for serviceability and eventual recovery—may be the right call. For a two-month internal display program, a moisture-resistant fibre-based solution with mechanical fixings may be smarter in terms of weight, cost, and disposal. Your role is to match the material to the objective and make the end-of-life outcome intentional.

When you do specify metals, state the full life story. When you specify fibres, state the real recovery route available in your region. When you need polymers, be clear about durability, maintenance and eventual take-back or disposal. Specificity is your best defence and your best sales tool.

Final word

This industry moves fast. Your clients will keep raising the bar; sustainability regulators won’t lower it. That’s fine. With clear material knowledge, a bit of structured testing, and straight-talking communication, you can deliver work that meets the brief, protects the margin, and reduces harm—job after job and be sustainable.

If you remember nothing else, remember this: design for disassembly, keep constructions simple, talk to suppliers early, and be specific in your sustainability claims. Do that consistently and stay credible, competitive, and proud of the work you put on shop fronts, exhibitions, vehicles, walls, windows, and floors across Canada.

The future isn’t about chasing environmental labels. It’s about doing the work, proving it, and helping your clients do the same. That’s how we move from intent to delivery—at pace, with fewer surprises, and with better results for everyone involved.

|

Steve Lister is a leading sustainability consultant and educator to the sign and display industry with Make it Happen Signage Consultancy. He founded SteveLister.com and is a sustainability consultant to global brands, retailers, and supply chain partners.