Eco-solvents defy the odds

Innovations in eco-solvent printers, inks, and software continue to drive demand

Despite industry predictions several years ago that eco-solvent technology would yield market share to other printing technologies like UV or latex, eco-solvent printer demand has remained robust amid an overall expanding digital print market.

According to Transparency Market Research, the global digital printing market is expected to grow at a compound annual growth rate (CAGR) of 6.1 per cent from 2024-2034, reaching a size of more than $54 billion in 2034.1 The ongoing demand for eco-solvent technology has led manufacturers to continue to innovate their eco-solvent printer lineup, with exciting results.

Daniel Valade, Roland DGA product manager of digital print, talks with us about what’s trending lately in printer, ink, and software innovations for the eco-solvent segment and how these advances are leading to faster production speeds and outstanding print quality.

Ginny Mumm (GM): Has the market for printers been changing over the past few years? How would you describe it today?

Daniel Valade (DV): Over the past five years, the industry predicted a downturn in eco-solvent technology sales as users transitioned to other printing technologies, like latex or UV. However, the data shows there is still a strong demand for eco-solvent roll-to-roll printing technology today, due to its outstanding versatility and the fact that so many print professionals are familiar with eco-solvent printers.

As technology for all print devices advances, users are now looking for wide-gamut eco-solvent output devices that also provide strong production speeds to meet the challenging demands of today’s print customers.

GM: Overall, how are printer manufacturers responding to these changes?

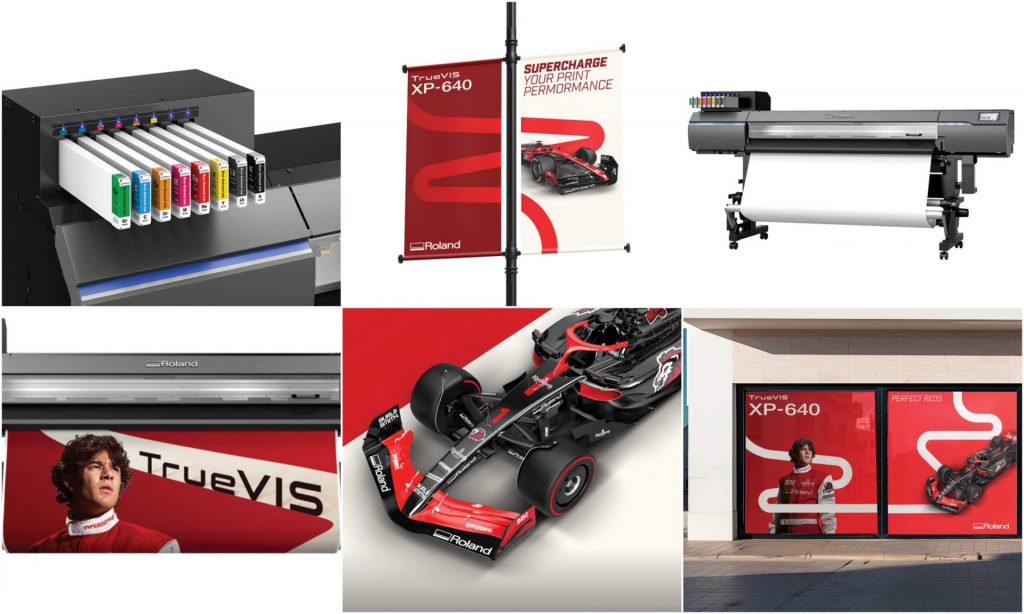

DV: We see manufacturers creating new eco-solvent output devices with wide-gamut ink sets, improved operating efficiency, and faster production speeds. Roland DG, for example, just released its TrueVIS XP-640 with dual staggered printheads that enable precise production while reaching speeds of up to 76 m2 (819 sf) per hour.

Manufacturers also offer more variety in their ink sets, allowing users to choose the configuration that best suits their needs. For some shops, the production speed of dual cyan, magenta, yellow, and key (CMYK) outweighs the benefits of a wide-gamut ink set, while others prefer the expanded range of colours they can achieve with an eight-colour ink set.

And finally, manufacturers are building in the extras that make print workflows easier, like an automatic media gap feature and plenty of presets to make colour matching simpler. All these elements increase the precision, speed, and overall productivity of today’s eco-solvent printers.

GM: Are there changes to software in this market?

DV: In recent years, Raster Image Processor (RIP) companies have been striving to make complex workflows as simple as possible. Several companies have created a simple front-end design that integrates with their RIP software, automating project workflows. Some RIP products, like Roland DG’s VersaWorks, offer advanced features such as True Rich Colour settings that, combined with its TH ink sets, make colour management easier than ever before.

The other area where software is having an impact is in the user-friendliness of these advanced eco-solvent devices. The XP 640, for example, offers a 177.8 mm (7 in.) control panel with an intuitive interface that facilitates an easy set-up process for nearly any application.

GM: What about media for these printers?

DV: One great feature of eco-solvent printers is their wide range of media compatibility, which makes them an incredibly versatile tool for print shop owners. There are thousands of different media designed for specific applications that can be used with an eco-solvent printer. Everything from decals, banners, signage, and vehicle wraps to window clings and even perforated printable window materials can be printed quickly and easily using eco-solvent inks.

Manufacturers are also assisting shop owners with media management. Some models include an automatic media take-up system that makes unattended printing available for today’s busy shop owners.

GM: Are there any innovations in inks?

DV: We consistently find that users are looking for more than just traditional CMYK printing and like having access to spot colours such as orange, green, red, and white. With an expanded colour gamut, they can hit previously unattainable hues and more closely replicate specific brand colours.

Customers are also looking for quick turnaround times and appreciate the newer, fast-drying eco-solvent inks that allow for same-day lamination or installation.

Manufacturers are responding with wider varieties of ink options that provide multiple benefits. As with most roll-to-roll eco-solvent devices, Roland DG’s XP-640 has very low running costs, averaging less than US$0.20 per 0.09 m2 (1 sf) and running as low as US$0.10 per 0.09 m2 (1 sf).

GM: What do you see ahead for the eco-solvent print market?

DV: The market share for eco-solvent has been large for quite some time and seems to be holding steady. As technology progresses and output devices get faster, there will continue to be opportunities for people to grow their businesses using their eco-solvent devices for years to come.

The available size range of eco-solvent devices is also evolving. Roland DG, for example, offers a suite of eco-solvent devices designed for entry-level to professional-level end users. These devices come in desktop to wide-format sizes, allowing users to choose which device works best for their production needs.

That said, other printing technologies are growing their market size. Options like latex and UV print appeal to customers with their ability to have instant lamination and same-day shipping or installation. Manufacturers recognize that eco-solvent production will need to continue innovating to maintain its market share.

Notes

1 Learn more about the Transparency Market Research report here: https://www.globenewswire.com/news-release/2024/08/22/2934453/32656/en/Digital-Printing-Market-Size-is-Anticipated-to-Achieve-a-Valuation-of-USD-54-4-Billion-by-2034-Exhibiting-a-CAGR-of-6-1-States-Transparency-Market-Research-Inc.html

Ginny Mumm is a freelance consultant for digital inkjet printer/cutter provider Roland DGA. For more information, visit www.rolanddga.com.