Understanding and installing environmental graphics

by Matthew | 1 May 2012 4:04 pm

[1]

[1]By Jeffrey Stadelman

For signmaking professionals seeking to excel in the installation of digitally printed graphics, it can be very challenging to keep informed of both the latest trends in the industry and the best practices in their field. With manufacturers constantly releasing new products, introducing new technologies and techniques for various applications, continuing education is crucial.

Graphic installers may not have easy access to expert advice for approaching the hurdles posed by the most challenging jobs. It is therefore important for industry veterans and newcomers alike to share information about graphic application, lamination and removal across the community through hands-on training sessions, demonstrations of tips and tricks and discussions of design theory, material properties and techniques for surface preparation.

Examples of outlets for education and the sharing of ideas include the Professional Decal Application Alliance’s (PDAA’s) master certification program, which focuses on vehicle wraps, wall and window graphics, building wraps, retail displays and fleet marking. There are also programs run by manufacturers of graphic media, including in-person sessions focusing on hands-on experience, as well as online databases of educational material for installers who may not have the opportunity to attend on-site seminars.

As application trends in the industry continue to evolve, these programs are focusing more on environmental graphics, which have seen increasing interest among users.

[2]

[2]Apply everywhere

As the name suggests, ‘environmental graphics’ are being applied everywhere in built environments, including walls, windows, floors, sidewalks and furniture. They are growing in popularity, enabled by many new products entering the marketplace. As a result, installers are finding it necessary to familiarize themselves with new products and their specific application requirements.

Compared to traditional graphic applications, environmental graphics involve special surface properties, adhesive chemistries, design considerations, laminating procedures and installation techniques. Many installers are giving due consideration to these factors as they shift their focus to expanding markets and new product categories.

The following are some examples of environmental graphics and the application challenges inherent to each.

Interior wall graphics

With today’s wide-format inkjet printers and their compatibility with a variety of substrates, signmakers can produce vibrant graphics that can easily be applied to walls painted with latex-based formulations, without the need for specialized tools.

Traditional cut vinyl marking films, for example, have moved from vehicle wraps and trade-show graphics to the home décor market, creating unique designs and ‘wall words,’ and are available in matte and gloss finishes. These films are combined with semi-permanent solvent-based adhesives that can bond strongly to most wall surfaces and still be cleanly removed after use. Other specialty films designed for posters and other wall applications use an aggressive and removable acrylic-based adhesive and enable borderless graphics. There are even repositionable topcoated woven textiles that use acrylic adhesives to create upscale wall murals.

[3]

[3]These interior wall graphics can add artistic flair to hotels, homes and offices or serve marketing purposes in retail settings. Installers may need to take additional precautions when applying this type of media to more difficult surfaces, such as drywall and previously wallpapered surfaces, to ensure they can avoid a reinstallation later.

Exterior/reinforced wall graphics

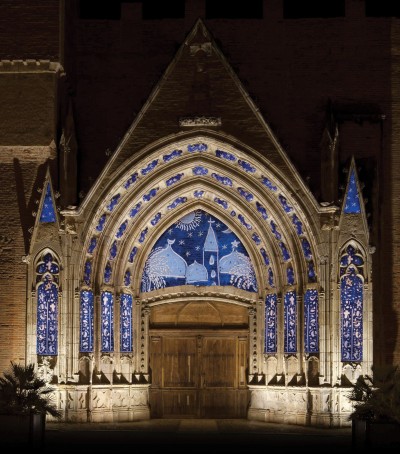

Exterior and reinforced walls can be more challenging, requiring wrapping films that are specially formulated for application onto coarse brick or cinderblock surfaces. These textured-wall installations would not be possible with traditional graphic materials.

The highly conformable polyvinyl chloride (PVC) materials engineered for these exterior applications are also formulated for added resilience under exposure to the elements. Even then, their adhesives require careful application and lamination to preserve them and ensure they will last.

Window graphics

Environmental graphics are also widely applied to windows to augment décor, ensure privacy and/or convey a marketing message to passersby. A number of window film types are available, offering different esthetics and levels of transparency, ranging from a translucent-frosted or dusted-matte finish to a clear-gloss finish.

It can be difficult to install graphics on a window without trapping air bubbles beneath the film, which may cause wrinkling. A wet application method will help when working with traditional window films, but another mess-free option is to use special ‘bubble-free’ media, which are available in a variety of finishes. These films can be applied dry because they carry a smooth and omnidirectional ‘air egress’ adhesive, which allows the air to escape, rather than become trapped.

Graphic installation professionals will need to learn the differences between various window film adhesives and the best installation techniques for each product.

[4]

[4]Floor and sidewalk graphics

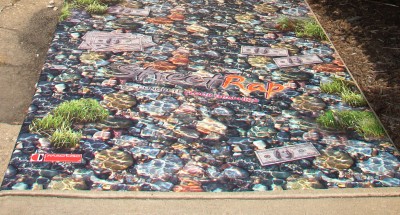

Some of the more novel uses of digitally printed graphics in recent years have been applications at ground level. Gloss- and matte-finish calendered films are available for installation on floors, sidewalks, asphalt, concrete and even carpeting.

A complete floor graphic system includes performance-matched base films and overlaminates, ensuring the graphics will withstand foot traffic and be safe to walk upon. There are special surface and friction considerations with floor and sidewalk graphics, so it is important to understand the roles of both films and overlaminates and to ensure the proper American Society for Testing and Materials (ASTM) tests are performed to confirm quality.

Case Study: The Printing Services

When vitamin producer Organika wanted a large vinyl ad and Your Vitamin Store (YVS) sought to spruce up its window display, The Printing Services in Richmond, B.C., turned to bubble-free window film to meet both needs with reverse-printed graphics. The company paired the material with a white gloss vinyl backing, both to protect it and to provide a crisp backdrop for the colourful images.

“For this project, we had to divide the graphic into two pieces and then match them up flawlessly, which was the biggest challenge,” says Gilbert Yu, business consultant. “It took two of us three hours to install the graphic dry. After the job was done, the sign caught the attention of a lot of shoppers walking by YVS, because it was the only large window graphic in the mall. Our clients were very impressed with the results.”

Case Study: DeSigns Group

A grand-scale ‘billboard’ graphic that stretched over an entire block in downtown Vancouver to advertise the Patina Concert condominium development comprised nearly 139 m2 (1,500 sf) of printed media in three large sections. Conceptualized by the Idea Partner, it was produced as a building wrap by DeSigns Group in Delta, B.C.

“We used a matte white calendered film for this design, as its strong acrylic adhesive adds reliability and longevity to signs in this varied-weather region,” says Wayne Smutylo, owner of DeSigns Group. “The opaque blockout property is key, allowing the client to change graphics as the project evolves through selling phases without deinstallation.”

[5]

[5]Installation took five days to complete, applying each 1.2 x 3-m (4 x 10-ft) vinyl section in turn.

Don’t underestimate overlaminates

In addition to protecting digitally printed environmental graphics from various stresses, foot traffic and the elements to ensure safety and durability, overlaminates can also enhance their appearance and make their installation easier by adding rigidity.

Like the printable films to which they are applied, different overlaminates are specifically designed for certain types of applications. It is important to choose the correct material for the job, based on that material’s properties and lamination process.

Traditional overlaminates are available with matte, gloss or lustre finishes. Textured laminates, meanwhile, can provide high-profile finishes, image enhancements and protection for high-end architectural graphics, interior décor, point-of-purchase (POP) displays, decals, furnishings, floor graphics and sign applications. Texture options include fine and coarse wood grain, brushed metal, flock, carbon fibre and leather, supporting a wide range of creative concepts.

Determining which type of overlaminate—if any—best suits a given project and then knowing how to install it efficiently can make a big difference for graphic applications in terms of time and money.

Stay informed and successful

As environmental graphics continue to gain prominence in the digital printing industry, it will remain important for signmakers to keep informed about the latest technologies, installation techniques and trends. By networking with other installers of graphics to seek out advice and inspiration, whether in person or via online communities and social media networks, they can ensure they will be ready for the challenges of tomorrow.

Jeffrey Stadelman is technical marketing manager for Mactac Graphic Products, which produces pressure-sensitive vinyl, overlaminates, mounting and marking films and other media for wide-format digital printing and screenprinting. Mactac also manages the Application Nation, an online community of graphic application specialists sharing standards, education, ideas, trends and techniques. For more information, visit www.mactac.com[6] and www.theapplicationnation.com[7].

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/RoughRap-Image_Cathedral.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/C-A4-ImpressionDigital_8900-product.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/DecoSatin.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/Bfree-Window-Film.jpg

- [Image]: http://www.signmedia.ca/wp-content/uploads/2014/02/StreetRap.jpg

- www.mactac.com: http://www.mactac.com

- www.theapplicationnation.com: http://www.theapplicationnation.com

Source URL: https://www.signmedia.ca/understanding-and-installing-environmental-graphics/